Process design using forced dough relaxation

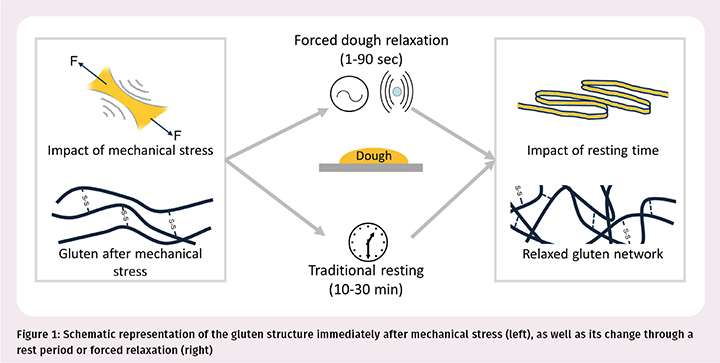

By means of invasive mechanical and electrical impulses, the dough resting time of wheat doughs after mechanical energy input can be drastically shortened.

By means of invasive mechanical and electrical impulses, the dough resting time of wheat doughs after mechanical energy input can be drastically shortened.

A characteristic all trays have in common, regardless of endless possibilities in their layouts, is the safety guarantee provided for the products baked, time and again.

Cleaning can quite literally make or break the trays, respectively their life expectancy.

Transport crates for baked goods do not appear to differ much at first sight. They only vary in color, weight and height. However, when it comes to cleaning the crates, the situation is very different.

There are both automatic and manual solutions for cookie production.

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/Riss, offers various processes.

As a basis, the hygienic risk to food safety/shelf-life is taken as an example for baked goods. Subdivision takes place according to the hygiene sensitivity of the respective products. The basis

is always an assessment of the respective product