RBS launches ambient cooling conveyor for cracker systems

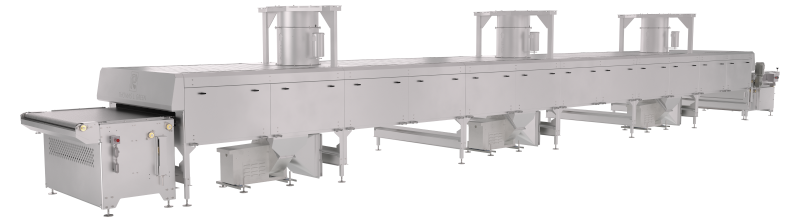

Reading Bakery Systems (RBS) introduced a new ambient cooling conveyor, with increased efficiency in cooling crackers before entering packaging in a more‐compact footprint.

Reading Bakery Systems (RBS) introduced a new ambient cooling conveyor, with increased efficiency in cooling crackers before entering packaging in a more‐compact footprint.

Reading Bakery Systems announced it expanded the features and services of its proprietary Industrial Internet of Things (IIoT) platform, RBSConnect, to include the latest in custom-designed control systems.

Better baking for biscuits and cookies means matching the intended baking curve of the product, stage by stage, consistently and efficiently. With its Emithermic oven, Reading Bakery Systems provides complete control over five baking parameters that create a more balanced bake.

Continuous dough production is designed with volume and efficiency in mind. Requirements stemming from the product characteristics, the manufacturing needs,

Reading Bakery Systems, a member of the Markel Food Group, has re-engineered the MX Continuous Mixer. The model now ranks as the most versatile continuous mixer, and is suitable for a broad product spectrum and a wide diversity of doughs.