RBS launches ambient cooling conveyor for cracker systems

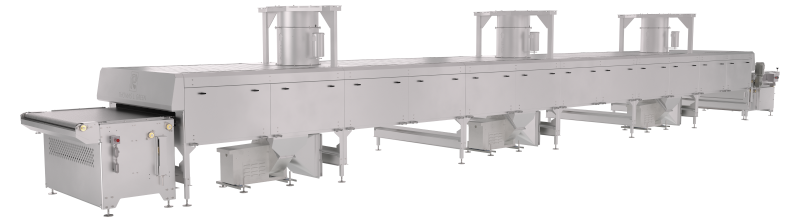

Reading Bakery Systems (RBS) introduced a new ambient cooling conveyor, with increased efficiency in cooling crackers before entering packaging in a more‐compact footprint.

Reading Bakery Systems (RBS) introduced a new ambient cooling conveyor, with increased efficiency in cooling crackers before entering packaging in a more‐compact footprint.

Reading Bakery Systems announced it expanded the features and services of its proprietary Industrial Internet of Things (IIoT) platform, RBSConnect, to include the latest in custom-designed control systems.

Requirements stemming from the product characteristics, the manufacturing needs, the facility and equipment line-up will influence how continuous mixing and kneading should be set up.

Better baking for biscuits and cookies means matching the intended baking curve of the product, stage by stage, consistently and efficiently. With its Emithermic oven, Reading Bakery Systems provides complete control over five baking parameters that create a more balanced bake.

A continuous kneading and mixing process ensures all types of ingredients are mixed and kneaded in the optimum sequence to produce the desired product with consistent characteristics while saving time, resources and minimizing waste.

As crackers exit the oven, the cooling process is important to guarantee product quality and a long shelf life. A gentle cooling process will ensure the delicate product’s integrity until it is ready to be consumed.

To consistently produce high-quality pizza, especially at high speeds in industrial environments, all types of equipment on the production line must contribute.

In the industrial baking of any type of bread, and a multitude of other product ranges, tunnel ovens are the giants of large-volume, continuous baking, for which efficiency is a must.

In the industrial baking of any type of bread, and a multitude of other product ranges, tunnel ovens are the giants of large-volume, continuous baking, for which efficiency is a must.

Future Foods was established as a start-up company in 2016 near Cairo, Egypt. Its main focus is the snack market in Egypt and the MENA (Middle East, Near Asia) region and it has a particular speciality called a “Fretzel”.

Wolf ButterBack KG, a premium frozen baked products manufacturer in Fürth, is growing dynamically and is investing around EUR 50 million in a new third factory. The company had to expand production capacity to meet rising demand.

The Oetker subsidiary Wolf ButterBack KG plans to combine conventional and new, and on the one hand remain a loyal supplier to artisan bakers through wholesale organizations, while on the other serving new sales channels as well as European countries abroad.