VMI brings Phebus mixer to IBIE 2022

VMI shared in an interview the latest solutions that will be presented at its IBIE booth this year, in Las Vegas, from the latest planetary mixer, Phebus, to the Virtual Reality area.

VMI shared in an interview the latest solutions that will be presented at its IBIE booth this year, in Las Vegas, from the latest planetary mixer, Phebus, to the Virtual Reality area.

With over 8,000 new patisserie product launches every year, the challenge for industrial bakers is to diversify their offers by developing innovative creations that also pass nutritional checkpoints and provide an exciting eating experience, through an efficient manufacturing process.

Continuous mixers allow for all parameters to be constantly monitored and saved digitally, including ingredient stream rates, dough temperature, mixing energy input, throughput, mixer shaft speed, coolant temperatures, starts and stops, ingredient refill status, ingredient totalizers, dough totalizers, and many others.

Continuous mixers allow for all parameters to be constantly monitored and saved digitally, including ingredient stream rates, dough temperature, mixing energy input, throughput, mixer shaft speed, coolant temperatures, starts and stops, ingredient refill status, ingredient totalizers, dough totalizers, and many others.

Continuous mixers allow for all parameters to be constantly monitored and saved digitally, including ingredient stream rates, dough temperature, mixing energy input, throughput, mixer shaft speed, coolant temperatures, starts and stops, ingredient refill status, ingredient totalizers, dough totalizers, and many others.

Automated continuous mixing delivers real-time process assessment and consistency round the clock.

Automated continuous mixing delivers real-time process assessment and consistency round the clock.

Notable examples we looked into include Koenig’s new generation of roll lines – the KGV Plus, and the latest addition, KGV EC that was just launched at iba.CONNECTING EXPERTS mid-March.

A continuous kneading and mixing process ensures all types of ingredients are mixed and kneaded in the optimum sequence to produce the desired product with consistent characteristics while saving time, resources and minimizing waste.

The principle of the forked kneader came from the Mahot machine factory and provided mechanization of dough preparation. It has since proved itself in practice – and is still used today. The reason behind this is the technological proximity to French traditional, manual dough production.

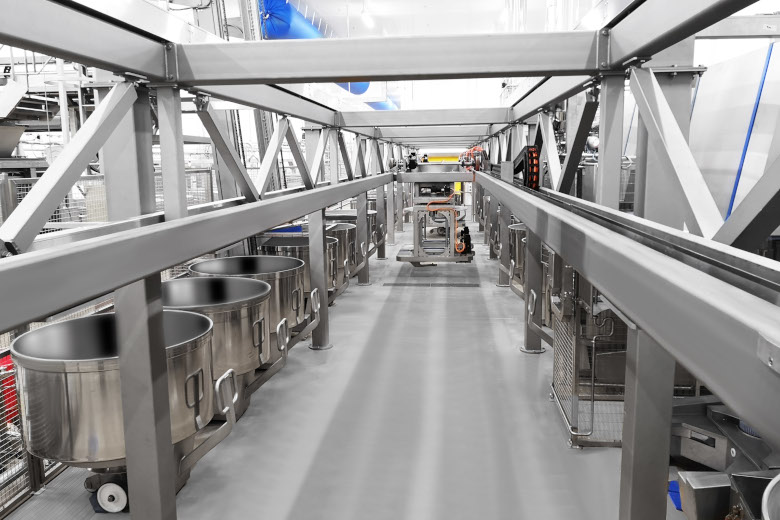

VMI’s VERYMIX kneader is recommended for the continuous production of raw frozen, parbaked and/or pre-proofed and frozen doughs, including baguettes, ciabattas, pizzas, Viennese pastry, puff pastry and flour & water mixtures.

RONDO observes special donut shapes are increasingly in demand, and so is the flexibility to produce them all on one line, which also makes fast changeovers a necessity.