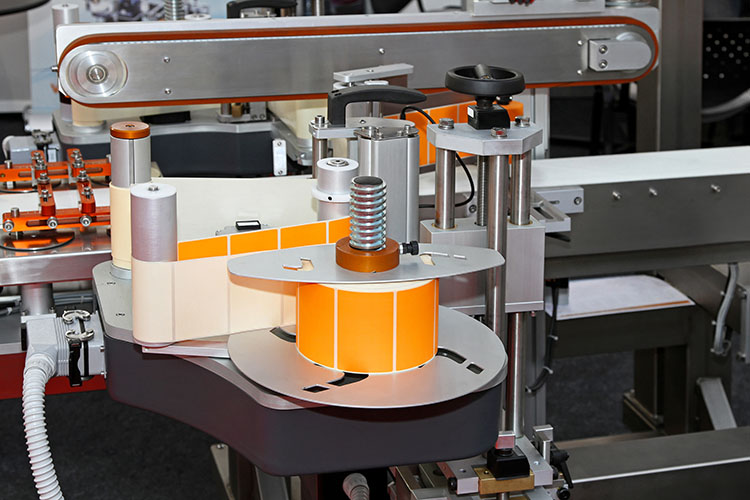

“Using artificial intelligence to analyze data on labels”

Mixing up label rolls in production is every food manufacturer’s nightmare. Visual inspection of the products is time- consuming, personnel-intensive, and still carries risks.

Mixing up label rolls in production is every food manufacturer’s nightmare. Visual inspection of the products is time- consuming, personnel-intensive, and still carries risks.

There are both automatic and manual solutions for cookie production.

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/Riss, offers various processes.

The COMJET with the WP Robot promises professional lye application combined with a robotic cutting plant.

Minebea Intec, Hamburg, the German part of MinebeaMitsumi, a globally operating group (annual sales revenues EUR 7.3 billion), specializes in

The GEA Comas DV3 Multi-Depositor system allows simultaneous extrusion and deposition of two doughs and an additional medium-viscosity filling input.

At booth 7469, Aasted, Farum/Denmark, will present a wide range of process technologies ranging from dough forming to adding value to products with chocolate decorations or enrobing. The exhibits also include the new Alice™ II, the next generation of extruder as well as the Alice™ High-speed wire cutter, which is even more refined, faster and easier to use.

New digital technology provides a better way to measure humidity in proofers, oven, dryers and cooling tunnels.

Bakers weigh out their raw materials by the shovelful – that may have been true in earlier centuries, but nowadays surveillance authorities and raw materials prices both equally ensure that weighing, monitoring and subsequent analyses accompany the entire production process.

Pizza production is one of the key points of expertise of Kaak’s Italian MCS subsidiary from the northern Italian commune of Ala. The Italians’ latest highlight is a new, fully automatic pizza press.

Reading Bakery Systems (RBS) is one of the world’s leading manufacturers of baking and process systems, especially in advanced high production cookie, cracker, biscuit, snack (baked chips, pretzels, expanded snacks, and bread snacks) and pet food systems.

Bundy Baking Solutions is an American company with a family of brands that includes American Pan and Shaffer Mixer.