DIOSNA introduces IoT solution

DIOSNA launched a new IoT solution for dough production. The system monitors the condition and product quality through live data. It can be accessed remotely.

DIOSNA launched a new IoT solution for dough production. The system monitors the condition and product quality through live data. It can be accessed remotely.

Innovation in Artificial Intelligence algorithms can be applied to baking processes for improved results.

A versatile piece of equipment that can be used for all processes requiring controlled temperatures is the spiral. For this technology, Ashworth developed the SmartSpiral® Monitoring System, an application that provides real-time monitoring of multiple spirals, even over different facilities.

Kaak lines are used both for dough balls, which can be stored chilled until they are shaped in production or in the store for some days, as well as for complete lines that either press dough portions to the base using the hot or cold process or from the ‘cut out’ of a dough sheet.

Small baked goods production: Innovative dough dividing, forming and depositing in a single step with the FS 520 forming system.

Mixing up label rolls in production is every food manufacturer’s nightmare. Visual inspection of the products is time- consuming, personnel-intensive, and still carries risks.

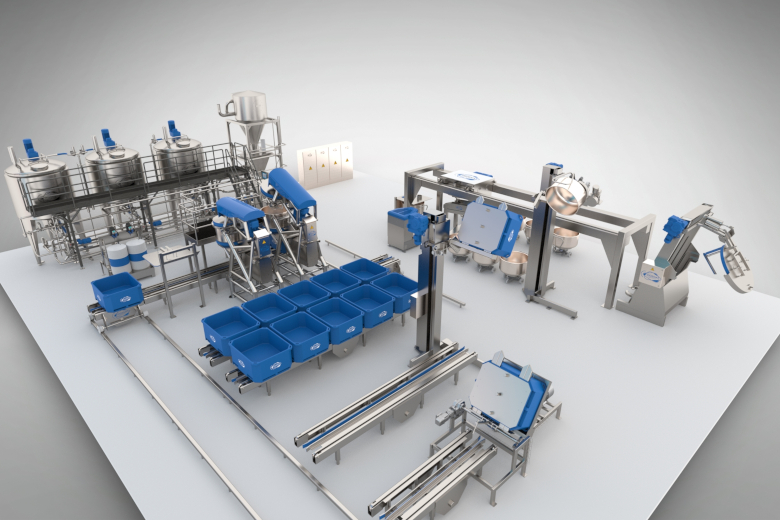

For the production of small pastries, the plant manufacturer Handtmann offers solutions for fully automatic production.

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/Riss, offers various solutions for the industrial production of toast-bread.

There are both automatic and manual solutions for cookie production.

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/Riss, offers various processes.

Minebea Intec, Hamburg, the German part of MinebeaMitsumi, a globally operating group (annual sales revenues EUR 7.3 billion), specializes in

Koenig Bakery Systems, Ashland/USA, will showcase its baking equipment at IBIE 2019. The very compact Mini Rex Multi dough divider and rounder features a new forming station – it can now also produce Teleras & Bolillos.

WP-Haton concentrates on making up doughs by classical methods using dough dividers, rounders, long rollers and proofers. The focus is on excellence and flexibility.