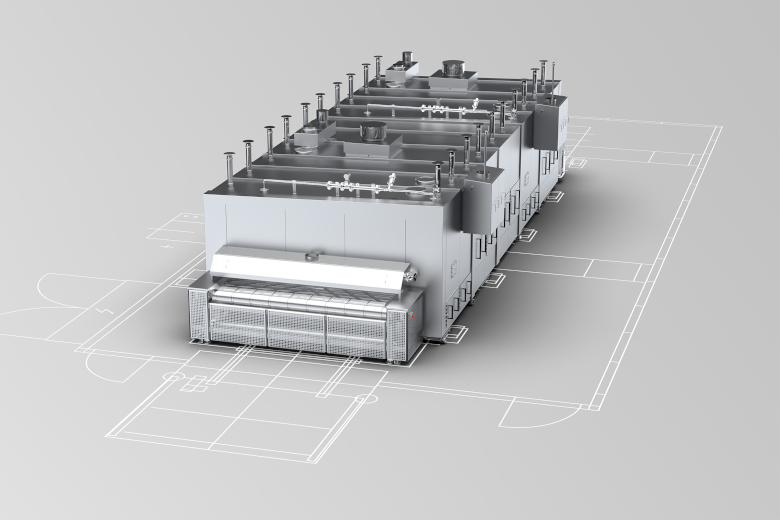

MECATHERM introduced its new M-DAN Oven, an evolution of the FDAN Oven technology, at interpack. The M-DAN Oven is dedicated to the production of delicate products and its design prioritizes hygiene and food safety.

It was developed to meet the baking requirements of delicate pastry products, dairy desserts, vegetables, plant-based protein products, and other savory dishes such as meat and cheese-based pastries, explains MECTHERM.

Ease of cleaning

To meet hygiene requirements, MECATHERM developed an oven that facilitates cleaning operations that need to be carried out several times a week or even daily, depending on the products. It can be cleaned with large amounts of water, thanks to a draining system collecting the water. Ergonomic side access doors and access hatches installed on both sides along the entire length of the oven facilitate access to the baking chamber and conveyors. The oven is also equipped with automatic rotating brushes for cleaning belts and low drawers for easy recovery of solid residues after baking.

Baking precision and flexibility

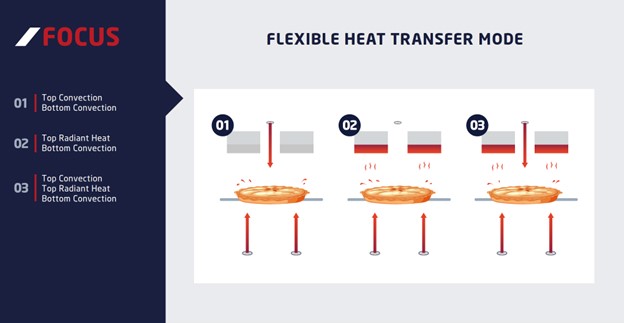

The M-DAN oven controls the temperature curve and features three heat transfer modes. The oven’s modular construction offers compact and independent heating zones, to precisely adjust and combine heat flows (convection and/or radiation), heating intensity, and airspeed to achieve the desired baking results. This baking precision is particularly useful for products with liquid fillings.

Energy efficiency

The M-DAN Oven offers a baking surface of up to 230m². Additionally, it quickly regulates temperature to optimize baking time and allow product changeovers. The combination of radiation and convection and the real-time modulation of baking also significantly minimize product losses by avoiding ‘flash heat’ during start-ups and production changes, MECATHERM explains.

Sustainability features

The low-temperature convection baking of the M-DAN reduces energy losses with optimized baking times and cooler smoke emissions. The oven also has fine moisture management via the assistance function for adjusting the opening of the damper. This removes excess steam from the baking chamber and precisely manages air entry, avoiding any unnecessary heat loss.

Designed to optimize energy consumption and reduce CO2 and nitrogen oxide (NOx) emissions, the M-DAN Oven works equally well with gas-fired thermal generators or electric resistance batteries.

The oven is also compatible with MECATHERM’s M-Care digital solution.

“With our new M-DAN Oven, we meet the needs of industrial users in search of a reactive, precise, efficient, and high-performance oven for baking their delicate pastry items, dairy desserts, vegetables, plant-based protein products, and other savory dishes, such as meat and cheese-based pastries. It meets the challenges of flexibility and energy efficiency while being particularly easy to operate and clean. Its high level of cleanliness is undoubtedly a major asset, achieving compliance with the strictest sanitary standards without wasting time on tedious cleaning operations,“ explains Xavier Gotti, Oven Product Manager at MECATHERM.

“The recent development of the M-DAN Oven is part of our mission to simplify our customers’ lives. Our teams are dedicated to developing innovative solutions to help them obtain sustainable success. At MECATHERM, we are continuously evolving our offers and investing in R&D to meet the daily challenges of product quality, industrial performance, and sustainability that the market faces,“ adds Raymond Nogaël, VP of Marketing and Business Development at TMG.

Photo: MECATHERM