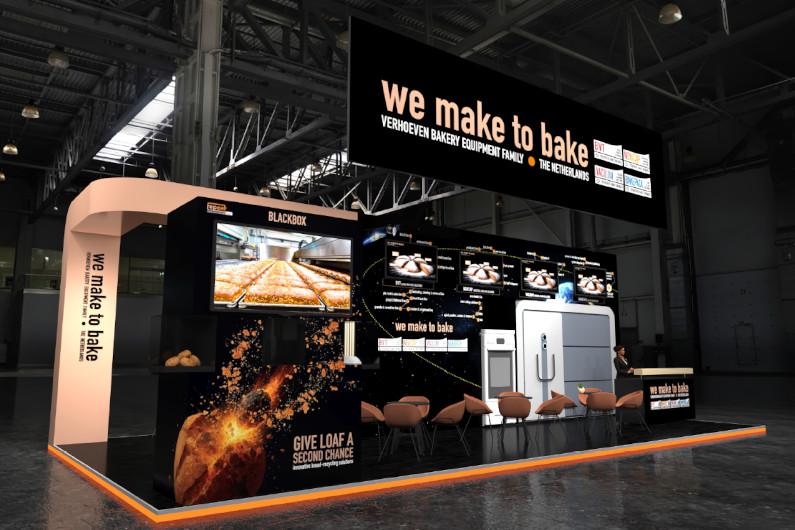

Verhoeven brings RepeatLoaf concept to IBIE

Verhoeven Family of Companies will introduce its latest sustainability concept in Las Vegas – a system that uses leftover bread and ferments it to be reused as a dry powder.

Verhoeven Family of Companies will introduce its latest sustainability concept in Las Vegas – a system that uses leftover bread and ferments it to be reused as a dry powder.

Verhoeven Bakery Equipment Family developed the Repeatloaf initiative to contribute to lowering waste in the baking industry. It offers an automated solution that upcycles leftover bread.

Verhoeven Family of Companies launched its latest technology, its vacuum cooling and baking technology, remotely. However, equipment testing and adjusting the process to the specifics of the destination environment is key.

The companies in the Verhoeven Bakery Equipment Family, BVT, NewCap, Vacuum Cooling and Bakepack, together design turnkey solutions, which can range from mono-lines for bread specialties, for example, baguettes, to multi-bread lines for a multitude of products including artisan breads, rolls, buns, baguettes and many more.

An enticing range of breads is carefully crafted to answer the consumer’s unwavering love for a slice of wholesomeness, whether

With BVT’s turnkey line, product variety extends beyond sweet and savory pies, which by themselves make up for a diverse product range, to begin with. The fully automated Pieline can handle all types of pies, tarts and cakes.

Sweet or savory, pies are a perennial favorite among consumers. Highly specialized production lines are developed to ensure production meets quantity as well as quality needs, efficiently.

Sweet or savory, pies are a perennial favorite among consumers. Highly specialized production lines are developed to ensure production meets quantity as well as quality needs, efficiently.

The Rademaker Pie and Quiche line is developed to produce an extensive assortment of pies and quiches from all cultures, ranging from meat pies, fruit pies, egg tarts (such as the beloved Pasta del Nata) and cheesecakes, to Melton pies, pork pies and even quiches.

Vacuum cooling specialist Verhoeven Bakery Equipment Family recently developed three new systems to handle the process.

A game-changer in the baking process. Vacuum cooling and baking is recognized for its benefits, not just in processing speed, but also in stable results for delicate products. Vacuum cooling specialist Verhoeven Bakery Equipment Family recently developed three new systems to handle the process.

To consistently produce high-quality pizza, especially at high speeds in industrial environments, all types of equipment on the production line must contribute.