An enticing range of breads is carefully crafted to answer the consumer’s unwavering love for a slice of wholesomeness, whether it’s an artisan-style bread or roll, ciabatta, focaccia, or a baguette. It’s their time to shine, in all creative interpretations, with the technology ready to reliably back up production.

A relaxed dough makes the best bread. For artisan breads of European inspiration (and beyond), dough need not only to be stress-free during the process, but also well-hydrated, in many cases.

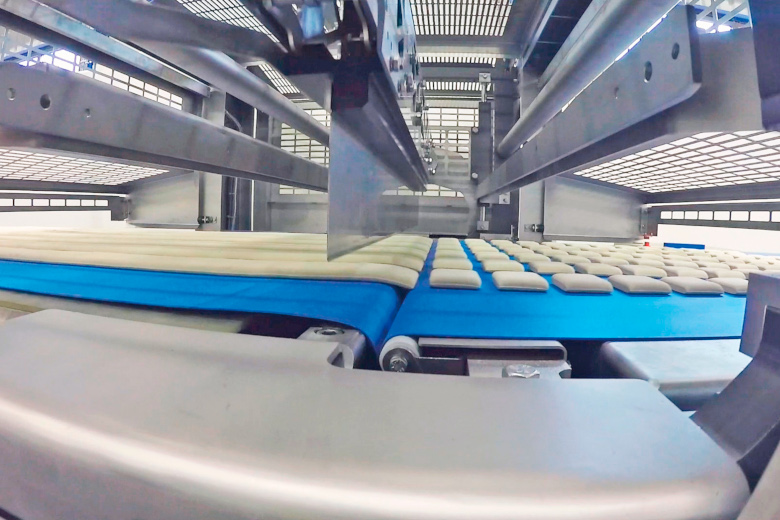

Rademaker: automated production of cut breads, rolled products

Rademaker designed its bread line for production efficiency, for a diverse range of breads including small baguettes, baguettes, triangle buns, square buns, hexagonal shaped buns, decorated/stamped buns, ciabatta, focaccia, pave, bagels and for a large variation of rounded products. It processes different types of dough, ranging from green doughs to highly hydrated doughs. Overall, any specialties in the categories of products that require the dough to be either cut, molded, or rounded can run on this line. Flexibility is ensured by its modular build, as well as fast changeovers.

Efficiency features are designed for every process. The sheeting section consists of quick reducers, cross roller and gauging stations to optimize dough sheet width and thickness. After sheeting, lane cutting and spreading, the dough is transported to the make-up section. Next, the make-up section will include units that help produce either cut, molded, or rounded products, with or without seeds. Throughout each step, the dough is tracked to ensure consistency at the desired parameters: “When the recipe is set and production starts by bringing the dough in the Double Chunker Stress Free System (DSS), the dough tracking is already working,” Rademaker illustrates. Dough tracking ensures the process flow is carried out as intended. For example, it can monitor if the flour sifters are switched on in time so that the dough always has flour when it arrives at the conveyor. It can also switch on a flour brush or a cross roller when required.

Cutting and stamping are made on a cutting table, with or without seal time technology. For fast changeovers, tools are designed to slide sideways onto a tooling trolley. The role of Rademaker’s own Double Chunker Stress Free System (DSS) pre-sheeting system in achieving the quality of the final product is essential. It is here that the dough batches coming from the kneader begin their journey as one continuous sheet of dough. “The DSS features two sets of chunker blades. The unit has a dynamic hopper that transports the dough in a controlled manner, keeping the shape of the dough chunks linear and constant. Landscape sensors and separate belts carefully guide the chunks in the sheeter, ensuring size and weight accuracy. The weight and length of each chunk are exceptionally accurate, which leads to a more stable and consistent dough sheet and eventually high-quality baked products,” Rademaker explains the operating principle of the technology.

The latest version of the DSS replaced the oil its predecessor used to prevent dough from sticking to the hopper with wax, while also reducing the amount to a quarter compared to the oil it used to require. This is great news for the production of some of the most sought-after ‘artisan’ breads, which require high levels of hydration or need (long) fermentation times making the dough inherently sticky, such as ciabatta, focaccia and pinsa. With the new DSS, cleaning is easier, “Cost-savings are considerable and the wax distribution system has a ROI of only 1 – 1.5 years. Equally important, the DSS using wax is more accurate on dough chunk weights due to the dynamic belt principle and, therefore, performs better overall, when compared to the oil DSS,” Rademaker explains. (Both oil and wax operating versions are available for the DSS, while the DPS is only available in the setup using wax)

The DSS and the corresponding dough sheeting section are designed to transport dough with minimal height differences, to preserve its homogeneity and structure. It also features easy access for cleaning. Moreover, it has a hygienic design and, with its wider belts, combined with advanced flour strewing and optimized waste bins, it supports clean working.

Hygiene is universally among the first production requirements in bakeries and this bread line is designed to meet all Rademakers’ Sigma hygienic design standards. The concept includes eliminating any recesses, cavities and dead corners and prioritizes round edges, tubes, ducts, angled surfaces and smooth finishings. In addition, an open design supports easy cleaning while maintaining the operator’s safety. “To keep the rollers of the reduction stations as clean as possible, they are fitted with wear-resistant roller scrapers,” Rademaker says.

The modular architecture of the Rademaker bread line makes it flexible for various configurations as well as changes over time.

The article is part of an in-depth feature published in Baking+Biscuit International, issue 1 – 2024.

Photos: Rademaker