Continuous baking in industrial bakeries answers production needs for volumes and consistency over time. However, it comes with several challenges that need to be managed to ensure efficiency, product quality and profitability.

For continuous baking setups, industrial operations optimize process efficiency and consistency in the end-result, namely quality. Continuous systems create and accurately maintain the target proofing and baking parameters, with a smooth product flow that ensures consistency. All process parameters, including temperature, humidity and airflow, are precisely controlled.

Unlike production running batch cycles, there are no limitations related to start/stop sequences while baking continuously. “A continuous system is based on conveyors that will carry every product through the same environment every time for maximum output, less waste and the lowest fuel costs,” specialists from AMF Bakery Systems highlight.

Automated baking and proofing

New, smart equipment helps capture a complete perspective of the entire chain of processes, in order to adjust each, and continuously ensure the line runs within the preset parameters. In an automated continuous system, the dough, pans and products never stop moving forward. In this way, each product undergoes exactly the same process, each in identical conditions, for uniform results. Proper proofing, for instance, relies on uniform airflow, without any hot or cold spots, so that every product is proofed under the same conditions, with no variations throughout the process. The target result is optimum product quality, at any time of the day, week, or season. Automated systems for continuous baking can be used for all the core product ranges made in industrial volumes, from buns and rolls to pan breads, balancing challenging textures with flavors and visuals.

environment every time for maximum output, less waste and the lowest fuel costs, with the smallest possible need for operator’s intervention or supervision.“

AMF Bakery Systems specialists

To provide the proofing and baking systems that ensure these results, AMF Bakery Systems has integrated smart software into its equipment. In this way, the technology specialist can design custom solutions for continuous baking setups, according to the unique product ranges, goals and challenges each operation works with (or around).

Smart systems bring several benefits, stemming from having processes closely monitored. Unexpected events are largely prevented from occurring: “Pan sensors are used and will notify in case of any irregularities that could potentially damage the system: if the wrong type of pan is detected, if two pans enter production stacked, or if pans are unevenly loaded, the operator will receive an alert,” AMF’s specialists illustrate. For each scenario, the required solution can be set in place to have the process continue undisturbed.

Automation also optimizes pan conveying – same-size spaces are created between the pans to ensure proper airflow, uniform heat and humidity, and that they remain stable in position in the proofer, for example. The proofer is designed to automatically run 20 air recirculations per hour (following AIB recommendations). While, “In the oven, pan tracking automatically reduces the burner’s output, depending on product load, to avoid overbaking products. Burners can also be completely turned off and back on again if a delay occurs,” explains AMF. Air recirculation in the oven is done with fans with variable speed drives, to control top and bottom air vectors according to the recipe requirements and to spread a controlled airflow over each pan in the oven. “Two sensors, for temperature and humidity, control the exhaust flow, for uniform programmable conditions even during changeovers and production dwells,” the specialist adds.

Man and machine

Staff monitoring and/or intervention is required for specific tasks. For example, product selection in the user interface is the first step in starting the automated process. In case pan guides are used, at the proofer in-feed level, they are usually manually adjusted every time a new product is selected. The oven and any product topping system located between the proofer and oven will also require the operator’s input. After the oven, the depanning systems may also have manual adjustments incorporated, if the pan orientation needs to be changed.

For cleaning processes, sanitizing the proofer can start as soon as the last product leaves the endless system. “A simple daily washdown with the automatic grid washer and a re-oiling of the endless chain (which is automated) are all that is necessary,” AMF explains. After a cooling down period, ovens can also be cleaned, by sweeping any toppings that may have dropped in. To keep the oven running for many years with no issues, a regular inspection of the burner systems is also recommended.

Under the hood

AMF BakeTech’s continuous proofer and oven systems feature robust track systems to ensure their stability over time. Both oven and proofer incorporate a unique dual-drive system, providing an even load distribution, with a built-in failsafe: two 1 HP load-sharing motors are used to drive the endless chain. This mechanism ensures production simply does not stop: “In the event of a motor failure, the redundant, backup motor can continue to drive the system without interruption until the time to service the faulty motor can be scheduled,” the specialist explains. Potentially extensive downtimes, with product losses, are no longer a risk, in this setup.

To further enhance their stability, these AMF BakeTech systems are designed with stainless steel gasketed and bolted track curves. For versatility, they are also interchangeable between proofer and oven, ensuring easy maintenance/replacement and lowering the need for spare parts. In this way, the track’s lifespan is also extended. “Service technicians only need a wrench to change a curve, while other welded track systems may require cutting, grinding and time-consuming rewelding to replace a curve or straight track,” AMF’s specialists observe.

To support different product ranges, from soft bread and rolls to artisan products and bagels, proofers can run magnetic pans or plastic peelboards; the oven, in turn, can bake products in pans, with or without steam, as needed for each specialty’s crust and color. “Automatic controls follow the recipe for each selected product, with a daily manual override possible, in case the processes before proofer were not carried out within the expected specifications,” AMF’s specialists says.

Direct Fire Dual Burner System

Moving on up

A bakery that is in the process of scaling up its production, for instance, can sometimes find challenges in the space they have available and in finding the right time for installations, while the existing lines continue to operate, or in between carefully planned downtimes. In addition, it is also essential to calibrate all processes for the same output, to avoid bottlenecks for some products, AMF’s specialists underline.

Setting up such a line is not without challenges. “Some batch processes can be employed along a continuous production line, sometimes – for example, mixing in batch mixers, or any proofer or oven loading method that requires collecting/grouping several pans,” AMF points out. Moreover, packaging and post-packaging machines with various degrees of automation can also be among possible sources of end results with aspect inconsistencies.

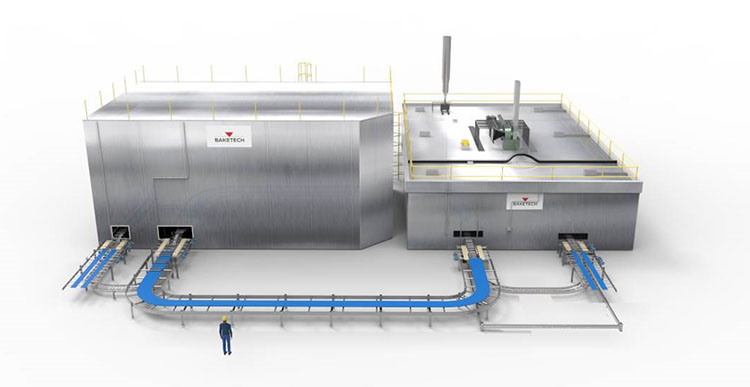

The AMF BakeTech Proofer and Oven Continuous System

The AMF BakeTech proofer and oven system can be used to bake up to 18,000 buns/hour.

Production rates can exceed 1,600 buns/rolls per minute, or 225 loaves of bread a minute, with a minimum need for workers’ intervention in the process.

In a recent automation project, such a proofer and oven system required four operators in bread production (not counting packaging, where a packaging/basket system was set up, with stackers/unstackers, washers, and product loaders, which needed a few more operators).

When a bakery upgrades to continuous proofing and baking from batch-based operations, results are immediately visible in product uniformity and the decrease in waste. “Once the product recipes are saved in the system’s memory, there are no daily changes to be made by the baker, all the agreed parameters are automated,” AMF explains. Over time, the fewer changes, the better, as this stability will translate into a higher output per hour, less ingredient loss and less energy consumption per unit produced. AMF’s automated baking solutions are designed to improve baking efficiency in industrial bakeries: the company’s application engineers determine and size the layout of each line to meet specific goals. Then, project engineers verify that the installation and commissioning are carried out to meet these goals, on-site.

Transitioning to continuous baking comes with some workflow changes. While, generally, automation means fewer people will be needed for processing, it can also come with higher needs for service technicians, so that the machines are maintained in top performance conditions. However, automation not only enables longer weekly uptimes, but often needs shorter scheduled downtimes to service the equipment, AMF points out. Bakeries can prepare in advance for such changes, while the exact line needed is being developed. After that, it’s baking around the clock, like clockwork.