Mondelēz focuses on minimizing food waste, with procedures that identify wastage hot spots in production. The company also joins initiatives aiming at avoiding it. During the last year, Mondelēz focused on making its production lines more efficient: it tracked waste trends every month, analyzing them to identify the best opportunities for reduction across all processes and geographies, with the goal of reducing manufacturing food waste by 15% by 2025 (compared to the 2018 baseline).

Continuous improvement focuses on waste generated, waste treated and waste to landfill. “While our primary focus is on food waste, we also analyzed all our waste management throughout the year to identify and act on all major opportunities,” Mondelēz reports.

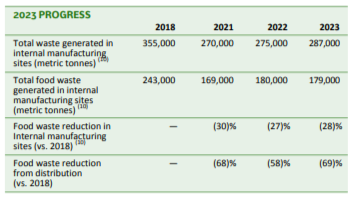

In 2023, food waste at its manufacturing sites was lowered by about (28)%, which is well ahead of its 2025 goal, the company estimates. In addition, a reduction of about 69% in food waste from distribution was achieved, surpassing its goal of around 50% for 2025.

“In Brazil, our Curitiba plant drove multiple scrap reduction and compost reprocessing flow optimization projects which have together resulted in a reduction of more than hundreds of metric tonnes of food waste compared to the previous year. Also in Brazil, our Recife plant focused on scrap reduction in the wafer and cookie lines delivering waste reduction,” the company highlights.

For example of projects aimed at raising awareness, Mondelēz co-created social media videos in Germany encouraging people to ‘LOOK, SMELL, TASTE’ before throwing away anything unnecessarily.

The 2023 Snacking Made Right Report can be accessed online.

Photo: Mondelez Snacking Made Right Report