By Charlotte D. Stemler, Judith M. Wießler, Katharina A. Scherf

Baking lipases have been used for decades as clean-label baking aids in bread. Recent studies show that they are also suitable for improving the baking quality of fine bakery goods such as cakes, by releasing surface-active molecules. Their potential in reformulating the recipe of an egg-free cake was then investigated in more detail.

This study analyzed the effect of seven lipases on the baking quality when reducing the butter content (by up to 50 %) and the water content (by up to 25 %). The lipases led to larger product volumes and resulted in easier-to-chew baked goods in all compositions. Lipases with a suitable substrate specificity were also able to maintain the softness of the original formulation, for all reduction levels. Consequently, baking lipases show great potential to enable recipe changes in cakes without any loss in baking quality and thus allow greater variability in recipe development.

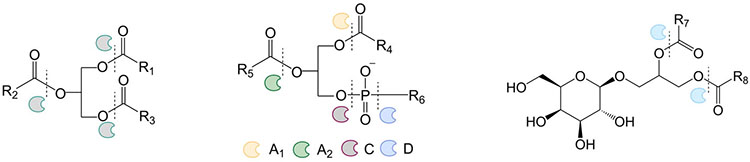

Lipases are enzymes in the hydrolase class and catalyze the cleavage of carboxyl esters. The term ‘lipases’ is used synonymously for enzymes with different specificities: in addition to triglyceride (TG) lipases (EC 3.1.1.3), which catalyze the hydrolysis of triglycerides to di- and monoglycerides, these also include various phospholipases (EC 3.1.1.32, 3.1.1.4, 3.1.4.3 and 3.1.4.4) and glycolipases (EC 3.1.1.26) (Figure 1). Although the substrates for the reactions are different, they all ultimately lead to the degradation of lipids and the simultaneous release of surface-active molecules.

Lipases as clean-label emulsifiers in bread

When lipases are added to bread, the resulting surface-active molecules act as emulsifiers.

Their effect on baking quality can be attributed to three main mechanisms (1):

1. The interaction with gas cells, whose interface they stabilize and thus enable higher product volumes;

2. The interaction with gluten, whose aggregation they promote and thus cause better machinability of doughs;

3. The interaction with starch, through which they act as ‘plasticizers’, leads to softer products both directly after baking and during storage.

Lipases are therefore effective baking aids for improving baking quality. Since they are also deactivated during the baking process and then no longer fulfill a technological function in the end product, they are legally considered processing aids (Regulation (EC) No. 1333/2009). This makes their use a clean-label solution.

Lipases have been used successfully in bread for decades. Current research is looking at ways of extending their use to other product groups such as fine bakery goods.

Fig. 1: Lipase cleavage sites. Left: Triglyceride (TG) lipase; center: phospholipases; right: glycolipase.

Possible applications of lipases in fine bakery goods

Compared to bread, fine bakery goods contain a wider range of ingredients. In particular, fat-containing ingredients such as butter and egg provide a variety of new substrates for degradation by lipases. New substrates lead to other, surface-active molecules whose effect on baking quality cannot be predicted. So, simply transferring the scientific findings for use in fined bakery goods is not possible. Current studies provide a first insight into new applications for lipases in fine bakery goods (2,3). Three different cake recipes were included in the studies to represent the variety of recipes for fine bakery goods. In addition to a classic pound cake and a yeast-based brioche, an egg-free cake recipe was also used. Seven baking lipase preparations that are successfully already used in bread were utilized as lipases. These included a TG lipase, a glycolipase and five phospholipases.

The results showed that the baking quality of batters/doughs and the finished bakery goods can be improved by using lipases. Doughs and batters were more machinable after the addition of lipases; for example, the stickiness of the cake batter was reduced by up to 43 %. In addition, lipase-treated egg-free cakes were up to 67% softer than untreated cakes when stored for up to 96 hours. By reducing the cohesiveness, the chewiness was also improved; in egg-free cakes – by up to 48 %, in pound cakes – by up to 25 %, and in brioche – by a maximum of 14 %. The effectiveness of the lipases was therefore influenced by the recipe. In addition, phospholipases proved to be more suitable than TG lipase and glycolipase. Which surface-active molecules and how many were released was decisive for how the dough and product quality were changed (4).

Study design

Based on these promising results, further potential uses of lipases in fine bakery goods are now being explored. As the greatest effects were achieved with the egg-free cake recipe, it was selected for further trials. It was investigated whether the addition of lipases could change the recipe without reducing the baking quality.

Butter is a crucial ingredient for baking quality. It ensures a soft texture by preventing the formation of a solid protein network. It also delays staling and therefore ensures longer-lasting baking quality. By stabilizing gas bubbles in the dough, it also leads to a higher product volume. However, the use of butter also increases the fat content of baked goods, which, together with the trans fatty acids it contains, increases the risk of cardiovascular disease. The butter content of egg-free cakes should therefore be gradually reduced to up to 50% of the original content.

Water is also essential for the baking process. It is added to the dough by various ingredients, often eggs (73% water content) or milk (87% water content), for example. Water interacts with the main components of the dough and enables the reactions required to form the typical, fluffy crumb. This includes, among others, the gelatinization of starch, the development of the gluten network and the activation of baking powder. However, an excessively high water content after baking leads to a high risk of microbial growth. The shelf life of bakery goods can therefore be increased by reducing the water content. However, if the water content is too low, a homogeneous dough or batter cannot be produced. For this reason, the water content was reduced by a maximum of 25 %.

Determination of baking quality

To prepare the egg-free cakes, 100 g butter with 50 g powdered sugar and 2.5 g salt were first mixed, until fluffy. Then, 250 g flour with 15 g baking powder and 200 ml water were added and mixed briefly. The seven preparations that had already been used in previous studies were used as lipases: phospholipases A, E, G, J and M; TG lipase O and glycolipase K. The dosage corresponded to the manufacturer’s instructions (70 – 500 mg/kg dough). The lipases were dissolved in water and added to the finished batter on a volume basis. Muffins weighing 50 g of dough each were baked (12 min, 180°C). For each combination of lipase and recipe modification, two muffins from three different batters were analyzed (n=6).

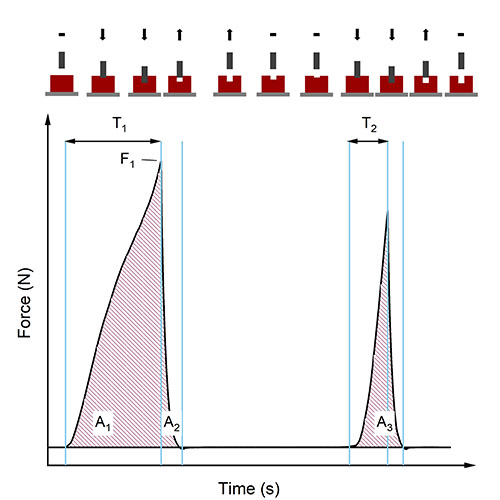

Fig. 2: Texture profile analysis. Schematic representation of the double compression test (movement of the measuring plunger to the sample) in conjunction with the resulting force-time diagram. Characteristic measuring points of the diagram for calculating the texture parameters firmness, resilience, elasticity and cohesiveness are marked (see text).

The determination of baking quality included the following parameters: density (volumetric), baking loss and the texture of the bakery goods. The effects of the lipases were investigated in comparison to control samples without lipase and to egg-free cakes with DATEM (monoacetyl and diacetyl tartaric acid esters of mono- and diacylglycerides of fatty acids, E 472e). Dunnett’s t-tests (p ≤ 0.05) were used to determine statistically significant changes due to recipe changes and/or lipase addition compared to the control.

The texture of the bakery goods was determined using texture profile analysis. The chewing process is simulated using a double compression, and a force-time diagram is recorded (Figure 2). A stamp compresses the crumb, releases it again and compresses it once more to a previously defined deformation. The firmness of the product is defined as the force required to reach the first maximum deformation (F1). The cohesiveness, i.e. the internal cohesion of the product, corresponds to the ratio of the area of the second peak and the first peak (A3/(A +A12)). To calculate the resilience, i.e. the resistance of the product, the areas of the first peak during compression and during relief are set in relation (A/A21) and the elasticity corresponds to the quotient of the time required for the first compression and the time required for the second compression (T/T21). Secondary parameters such as gumminess (product of firmness and cohesion) and chewability (product of gumminesss and elasticity) can be calculated from these four primary texture parameters.

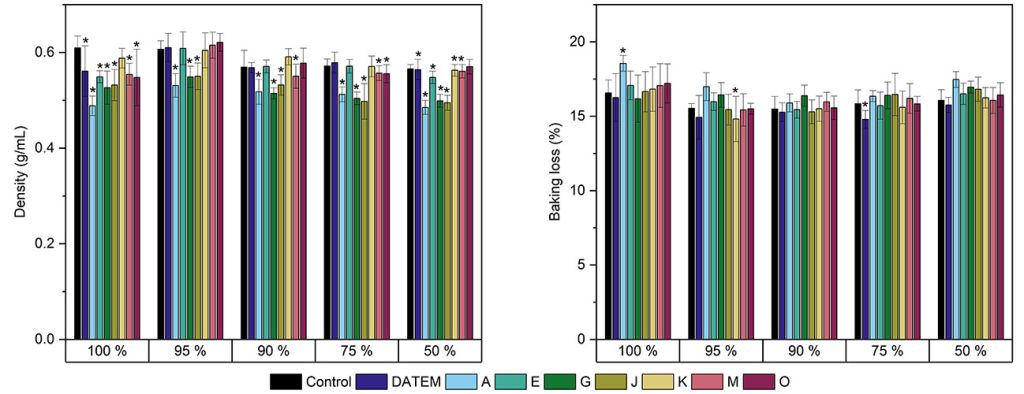

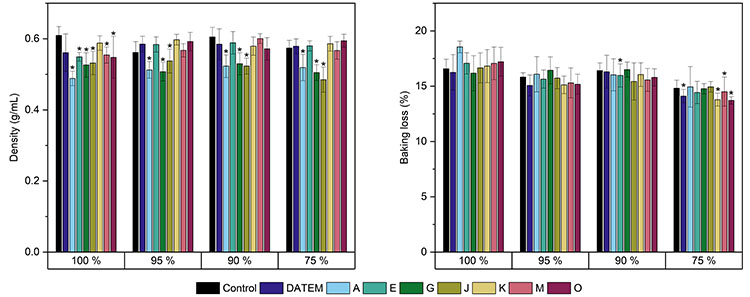

Fig. 3: The density and baking loss of cakes when the original amount of butter (100 %) was reduced to 95 %, 90 %, 75 % and 50 % and treated with the lipases A, E, G, J, K, M and O or the emulsifier DATEM (mean ± standard deviation, n=6). Asterisks show a significant difference from the control sample at 100 % butter quantity (Dunnett’s t-test, p≤ 0.05)

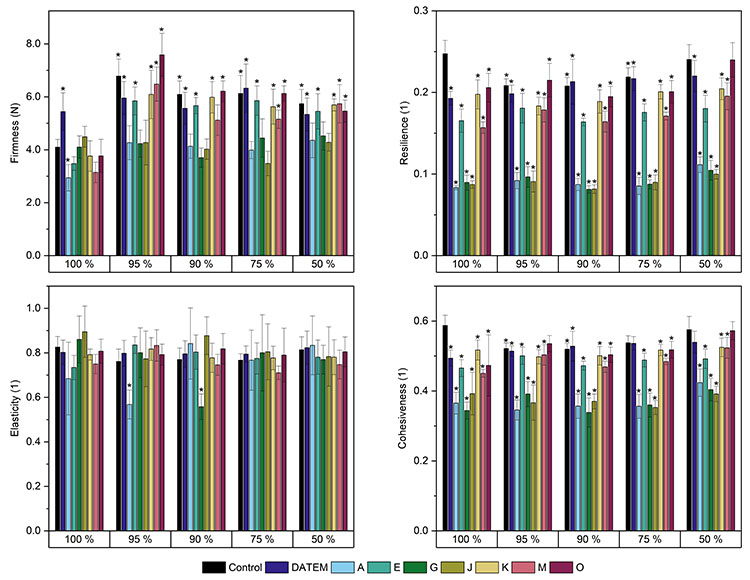

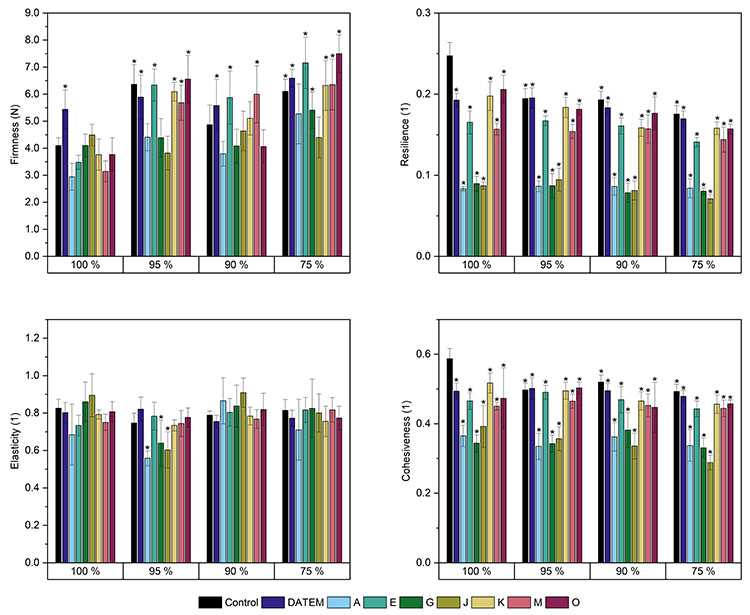

Fig. 4: The firmness, resilience, elasticity and cohesiveness of cakes when the original amount of butter (100 %) was reduced to 95 %, 90 %, 75 % and 50 % and treated with lipases A, E, G, J, K, M and O or the emulsifier DATEM (mean ± standard deviation, n=6). Asterisks show a significant difference from the control sample at 100 % butter quantity (Dunnett’s t-test, p≤ 0.05)

Potential of baking lipases in butter reduction

The butter content was reduced to 95 %, 90 %, 75 % and 50 % of the original amount. With suitable lipases, the baking quality of the original recipe was maintained even when the amount of butter was halved.

The density of the samples was between 0.49 g/ml and 0.62 g/ml. Despite the reduced amount of butter, the density and thus the volume of the untreated samples remained almost constant (Figure 3). Lipase addition resulted in higher product volumes for all butter quantities tested. Phospholipases A, G and J, which had already shown the greatest potential for improving baking quality in previous tests, had the greatest effect (2,3). DATEM also led to a reduction in density at 100 % and 50 % butter, but to a lesser extent than the lipases. Despite halving the amount of butter, sufficient substrates were available for the lipases to form surface-

active molecules.

The baking loss of the control samples was not influenced by the reduction of butter. It was between 14.8 % – 18.6 % for all samples (Figure 3). The water binding by the ingredients and, respectively, the baking loss were only influenced by lipases in individual cases (100 % butter and lipase A, 95 % butter and lipase K). In terms of texture, lipases improved the firmness, cohesiveness and resilience of the cakes (Figure 4).

As the butter content decreased, the products became harder; for example, the firmness of the control sample without additives increased from 4.1 N (100 % butter) to 5.7 N (50 % butter). DATEM also led to an increase in product firmness in all compositions compared to the control sample with 100 % butter. The addition of lipases made the cakes softer, so that a maximum firmness of 4.4 N was measured for the products treated with lipase A and 4.5 N for those treated with lipases G and J.

Thus, even at half the butter content, the products were not significantly harder than the control with 100 % butter without added lipase. Other lipases were less effective. Although some of the samples were softer than the control with the same butter content, they were significantly harder than the control with 100 % butter. Possible mechanisms for the ‘softener’ effect are the influence on amylose crystallization during cooling of the products and the influence on the number and distribution of gas bubbles in the product.

Resilience and cohesiveness behaved similarly to each other. When butter was reduced, the values of the control samples without lipases decreased slightly. The addition of lipases and DATEM significantly reduced both the resilience and cohesiveness of the samples at all reduction levels. Lipases A, G and J had a particularly strong effect, resulting in a maximum cohesiveness of 0.39 (control: 0.59) and a maximum resilience of 0.11 (control: 0.24). The other two phospholipases E and M were slightly less effective than lipases A, G and J. Glycolipase K had an even smaller effect and TG lipase O had the smallest impact (e.g. no significant reduction in cohesiveness or resilience at 50 % butter quantity compared to the control sample with 100 % butter). The effect on cohesiveness and resilience is attributed to the influence on the gluten network of the samples, although the exact mechanisms could not yet be clarified.

The elasticity of the cakes was not affected by the reduction of butter. Similar to the baking loss, lipases only had a significant effect in isolated cases (lipase A at 95 % butter content, lipase G at 90 % butter content). Lipases also had no effect on the elasticity of fine bakery goods in other recipes (2).

In summary, despite reducing the amount of butter by up to 50 %, three of the five phospholipases led to significantly larger cakes with better chewability (by reducing resilience and cohesiveness), while at the same time, the cakes did not become harder than the control with 100 % butter. Baking loss and elasticity were not affected. Two other phospholipases as well as a glycolipase and a TG lipase also improved the baking quality when the amount of butter was reduced, albeit to a lesser extent. The effects achieved by the lipases were greater than the changes in baking quality caused by DATEM.

Fig. 5: The density and baking loss of cake when the original amount of water (100 %) was reduced to 95 %, 90 % and 75 % and treated with the lipases A, E, G, J, K, M and O or the emulsifier DATEM (mean ± standard deviation, n=6). Asterisks show a significant difference from the control sample at 100 % water level (Dunnett’s t-test, p≤ 0.05)

Potential of baking lipases in the reduction of water

The water content due to added water in the recipe was reduced to 95 %, 90 % and 75 % of the original amount. With the help of suitable lipases, the baking quality of cakes was still higher than that of the control sample with 100 % water, even at the highest reduction level.

The density of the samples was similar to the density with a reduced amount of butter and was between 0.49 g/ml and 0.61 g/ml (Figure 5). The volume and corresponding density of the control samples without added lipase did not change significantly when less water was added. DATEM also did not affect the density. Lipases A, G and J led to a lower density at all reduction levels and thus increased the product volume (controls: 0.56 – 0.61 g/mL, lipases A, G and J: 0.48 – 0.53 g/mL). The stabilization of gas bubbles by suitable surface-active molecules in the batter therefore took place independently of the amount of water.

The baking loss percentage in relation to the original weight of the samples was not affected by the water reduction (Figure 5). Only when water was reduced by 25 % did glycolipase K, TG lipase O and phospholipase M as well as DATEM lead to a significantly lower water loss compared to the control sample with 100 % water. The reactions catalyzed by the lipases led, in part, to an increase in water binding in the batter at low water levels.

As the water content decreased, the texture of the cake became harder and lost resilience and cohesiveness. The elasticity was not affected by this (Figure 6). By adding suitable lipases, the texture properties of the control sample could be maintained even at 75 % water content.

Fig. 6: The firmness, resilience, elasticity and cohesiveness of cakes when the original amount of water (100 %) was reduced to 95 %, 90 % and 75 % and treated with lipases A, E, G, J, K, M and O or the emulsifier DATEM (mean ± standard deviation, n=6). Asterisks show a significant difference from the control sample at 100 % water volume (Dunnett’s t-test, p≤ 0.05)

The firmness of the cake was in the range of 2.9 N – 7.5 N. The water reduction increased the firmness of the control sample from 4.1 N to 6.1 N. The addition of lipases led to softer products with a reduced water content in comparison. At 95 % of the original water content, the samples with lipases A, G and J were not significantly harder than the control sample with 100 % water; at 90 % water, lipases K and O also achieved this effect. At 75 % of the original water content, only the two lipases A and J did not lead to a significant increase in firmness compared to the control sample with 100 % water. DATEM was unable to maintain the original firmness at any reduction level. Presumably, the faster gelatinization of the starch due to less available water leads to a harder texture, whereby surface-active molecules can change this process.

As described for butter reduction, resilience, and cohesiveness behaved similarly to each other when the water content was reduced. This reinforces the theory that similar mechanisms are responsible for both properties. For resilience and cohesiveness, a reduction in water content led to a decrease in the values of the control samples, for resilience from 0.25 to 0.18 and for cohesiveness from 0.59 to 0.49. Lipases and DATEM additionally amplified the effect, with the three lipases A, G and J again being particularly effective. The samples spiked with these had a maximum resilience of 0.09 (control: 0.25) and a maximum cohesiveness of 0.39 (control: 0.59). All changes to the control sample, both the reduction of the water content and the addition of lipases or DATEM, reduced resilience and cohesiveness. The products were therefore less gummy and easier to chew.

Also comparable to the reduction in the butter content, the elasticity did not change either by reducing the water content or by adding DATEM or lipases. Only the lipases A, G and J led to up to 32.5 % lower elasticity at 95 % of the original water content. As no clear trend is discernible, the measurement may have been influenced by other factors. It is conceivable that the change in gas bubble size and distribution caused the compression to occur differently.

To summarize the results for the reduction of water in the cake recipe, the addition of lipases produced larger and easier-to-chew cakes that were no harder than the control product, even when the added water was reduced by up to 25 %. In line with the results for butter reduction and previous studies on the use of lipases in cakes, three phospholipases led to greater improvements in baking quality than the other four preparations investigated.

Conclusion and outlook

The results of the studies on the potential of baking lipases in the recipe modification of egg-free cakes show that baking lipases enable greater flexibility in butter and water quantities. Their effectiveness clearly exceeded that of the commercially available emulsifier DATEM. Overall, the lipases led to larger product volumes as well as softer and easier-to-chew cakes. Preparations with suitable substrate specificity made it possible to reduce the butter content (and thus also the fat content) by up to 50 % and the added water content by up to 25 %. These findings can be used in particular in the development of new clean-label recipes, while enabling a more individual adjustment of the composition of cake recipes.

Funding information

This IGF project of the FEI was supported via AiF within the program for promoting the Industrial Collective Research (IGF) of the Federal Ministry of Economic Affairs and Climate Action (BMWK), based on a resolution of the German Parliament. Project AiF 20771 N.

Contact us

Charlotte D. Stemler (1), Judith M. Wießler (1),

Katharina A. Scherf (1, 2, 3)

(1) Department of Bioactive and Functional Food Chemistry, Institute of Applied Biosciences, Karlsruhe Institute of Technology, Karlsruhe, Germany

(2) Leibniz Institute for Food Systems Biology at the Technical University of Munich, Freising, Germany

(3) Technical University of Munich, TUM School of Life Sciences, Professorship of Food Biopolymer Systems, Freising, Germany

E-mail: [email protected]

Literature

1 Gerits LR, Pareyt B, Decamps K, Delcour JA: Lipases and Their Functionality in the Production of Wheat-Based Food Systems. Comp Rev Food Sci Food Safe 2014; 13: 978-89.

2 Stemler CD, Scherf KA: Improvement of cake baking properties by lipases compared to a traditional emulsifier. Food Chemistry: X 2022; 15: 100442.

3 Stemler CD, Scherf KA: Lipases as cake batter improvers compared to a traditional emulsifier. LWT 2023; 174: 114464.

4 Stemler CD, Geisslitz S, Cutignano A, Scherf KA: Lipidomic insights into the reaction of baking lipases in cakes. Front Nutr 2023; 10: 1290502.