Recycling has a significant role to play in our environmental efforts, but it isn’t always the best way to prevent or alleviate major environmental concerns.

Is recycling truly the primary solution to our waste reduction needs, as many people expect? Let’s start with the Environmental Protection Agency (EPA), the federal agency responsible for the concept of The 3 Rs: ‘reduce, reuse, recycle.’ According to the EPA, the more technical name for ‘The 3Rs’ is the non-hazardous materials and waste management hierarchy, developed ‘in recognition that no single waste management approach is suitable for managing all materials and waste streams in all circumstances.’

The same principle applies for bakeries when it comes to the 3 Rs. “An example might be the reuse of heat from ovens to heat the rest of the bakery; or equipment that automatically shuts off when the line is not in use which saves electricity costs,” Ron Cardey, Sr VP of Customer Engagement, KwikLok, illustrates.

The hierarchy ranks the various waste management strategies from most to least environmentally preferred. It emphasizes reducing, reusing and recycling, in that order, as the key to minimizing waste and maximizing sustainability.

Recycling is in the second tier of preferred solutions, just below reducing and reusing. There are three strong reasons for this:

+ Source reduction, which is the minimization of material and energy usage, is always the smartest thing to do, since it generates more value with less resource use. Put simply, it’s better to not create waste than to figure out what to do with it.

In bakery, properly closing a package reduces stale product and ultimately wasted food. Kwik Lok also highlights providing tamper-evident re-closeable packaging allows the consumer to have confidence in their bakery item as well as the ability to re-close the product. “Both decrease food waste, which is responsible for as much as 12% of greenhouse gas emissions,” Cardey underlines.

+ Recycling requires energy usage to collect, store, sort, process, and remanufacture products and packages. This is a key reason that home recycling programs are most successful in areas of high population density: the energy cost of driving recycling trucks among to houses that are not in close proximity in rural areas offsets the value of the materials being collected.

+ The consumption of products continues to grow, regardless of recycling activities. It’s generally recognized that at least 90% of the environmental impact created by consumer goods is caused by products, and only 10% by their packaging. Thus, reducing consumption – a form of source reduction – has far greater benefit in the reduction of material, energy and water use, along with generation of greenhouse gases and other pollutants.

Manufacturers, bakeries included, can lower their greenhouse gas emissions by adhering to strong food waste reduction programs, Kwik Lok observes.

Thus, for all its benefits, recycling by itself cannot, and was never intended to prevent or remediate major environmental concerns such as climate change, habitat destruction and loss of biodiversity. Its primary roles are the reduction of solid waste sent to landfills and minimizing the use of virgin resources.

New packaging materials can help: “Material science is a very big focus right now. Creating new materials with lower greenhouse gas emissions and that are responsibly sourced is something we are working to further develop,” Cardey details; responsible-sourced, bio-based materials are under development. Another area of importance in the manufacturing of baked goods is in-line automation, which can save energy and create lower emissions.

Recycling and climate change

Of the major environmental concerns, climate change is generally considered as needing the greatest global emphasis. Both the G7 in its latest Leadership Recommendations, and The World Economic Forum recognize it as our most pressing environmental challenge. These and most other scientifically aware governmental, nonprofit, and business organizations recognize that the most effective way to mitigate climate change is by reducing greenhouse gas generation, primarily carbon dioxide (CO2). Reducing our ‘carbon footprint’ is thus considered to be the most important strategy in the fight to mitigate global climate change. Programs such as the Energy Star program in the U.S. are helpful to businesses of all types in developing a plan to address carbon emissions. Are recycled or recyclable products more likely to reduce greenhouse gas generation, and therefore do a better job of remediating climate change than their non-recycled counterparts? Let’s look at the following example.

Useful resources

+ An Introduction to Life-Cycle Assessment for Packaging (Packaging Digest, Dec. 8, 2020)

+ Cradle-to-Resin Life Cycle Analysis of PET Resin, (NAPCOR, March 2020)

+ Use Less Stuff: Environmental Solutions for Who We Really Are (Robert Lilienfeld and William Rathje, Fawcett Books/Ballantine, 1998)

Plastic closures versus cardboard closures

What happens when we compare different materials that are used to make the same product? We decided to examine the greenhouse gases generated by the humble bread bag closure, made by a company called Kwik Lok. I recently analyzed the company’s new product called Eco-Lok, which is made from both traditional plastic and a plastic made from natural and renewable ingredients that include starch and glycerine.

The little Kwik Lok closure you see on bread and produce bags is made from polystyrene (PS), a cost-effective, fossil fuel-based plastic that is not readily recycled. (According to the EPA, PS represents less than 4% of plastic packaging

waste. This relatively low volume, and the material’s low economic value, make it generally uneconomical to be mechanically recycled.) Why is PS not recycled? “That’s because a secondary market for it has not yet been created. For a product to be recycled, there must be value to support the cost of recycling. At Kwik Lok, we understand and support the concept of circularity,” according to Cardey.

The company makes a similar product out of cardboard that contains recycled material. (And, while it is also technically recyclable, we doubt that many of them are recycled, given their small size and lack of recycling notification). This cardboard closure is also made from renewable resources such as wood or fiber.

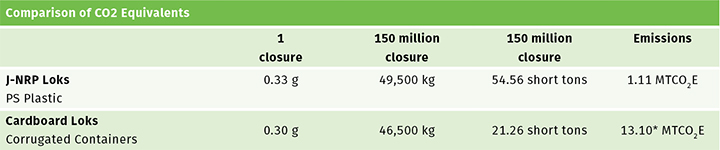

Which is more sustainable from the key perspective of greenhouse gas generation? The data below comes from the EPA’s WARM (Waste Reduction Model) calculator.

As you can see, the plastic closures weigh a bit more than the cardboard ones (6.5% to be reasonably exact). But they produce 92% less greenhouse gas emissions! What’s more, this is true even though the plastic closures contain no recycled content, while the cardboard ones do contain recycled material, generally up to around 25-35%.

About the author

Robert Lilienfeld has been involved in sustainable packaging for 25 years, working as a marketing consultant, editor, writer and communications expert. He is a regular contributor to a number of packaging and environmental magazines and journals.

Discussion

How can the plastic versions weigh more than cardboard closures, be made solely from virgin material, be produced from non-renewable resources, and still generate over 90% fewer greenhouse gas emissions? The answer is quite simple: It takes much less energy to produce closures from polystyrene than from cardboard, and greenhouse gas generation is a byproduct of energy use.

Is it possible to improve cardboard closures production so it can be a viable choice? It depends on the objective, says Kwik Lok: “In our work, we have learned that fiber or paper-

based solutions have a much higher carbon footprint. In addition, these solutions do not meet the needs of a wet or freezing environment.”

It’s also important to note that different plastics have different energy profiles. The PS used in closures is a much simpler and more efficient polymer to produce than the PET used in beverage bottles. (See Journal of Cleaner Production, Volume 17, Issue 13, September 2009, pages 1183-1194.) Differences in energy efficiency can significantly change the environmental footprint of the packaging in which various materials are used.

In fact, the production efficiency and the strength of plastics versus other materials are the key reasons why plastics began replacing other materials in the 1950s and 60s. The key metric is called the strength to weight ratio, and it measures how much weight a material can support in various forms – sheets, films, etc. As an analogy, plastics are the ants of the packaging world – light but extremely strong, with the ability to support far more mass than they themselves weigh.

While recycling/recyclability and use of renewable resources are important strategies in the effort to reduce the carbon footprint of packaging, the most effective strategy is to use the material that generates the least amount of carbon dioxide during its lifecycle of harvesting (or extraction), production, use, diversion and disposal. Depending on where, when and how energy is used, that material can be virgin, recycled, or some combination of both. The science of life cycle analysis is the clearest way to make this determination.