The conversation around increasing manufacturing sustainability will unavoidably start with analyzing ovens, for any baking operation. Visible results are a necessity.

An oven that bakes more sustainably should make use of energy efficiently and emit fewer greenhouse gases in the process while producingbaked goods of excellent quality. The variables are obvious; achieving the perfect balance requires expertise in technology and processes. Today, there are several options to choose from, each a possible fit according to individual and regional circumstances.

Sustainable technology options

From an energy efficiency standpoint, the conversion of electricity to bake is 1:1, making it 100% efficient. The added bonus is that emissions are 0%, in this case. Electric oven zones are also simple to operate and maintain. These are only some of the reasons why Reading Bakery Systems (RBS) sees the baking industry moving to electric ovens in the future.

RBS Electric Oven

The company first conducted tests and verified that the baking results when using electricity exclusively were the same as when using gas, in terms of quality, texture and taste. “RBS conducted hours of tests and R&D work that shows there are no significant oven performance differences between gas and electric power sources. Today, our electric penthouses allow RBS to offer all-electric versions of our latest Convection, Emithermic, and Emithermic XE oven zones,” the specialists explain. The electric penthouse offers one electric element per plenum, with dual blowers, allowing bakers to control top and bottom air speed and temperature independently. These ovens can be installed now with a gas-powered penthouse, and can easily be converted to use electric power in the future. Since a process line is used for three to four decades, machines acquired today will still be running in 2050. “Either buy green energy ovens now, or make sure you have a plan to convert it in the future,” RBS concludes.

“Knowing where the heat goes helps RBS design more energy-efficient ovens, something our engineers have been working on for decades.”

Reading Bakery Systems specialists

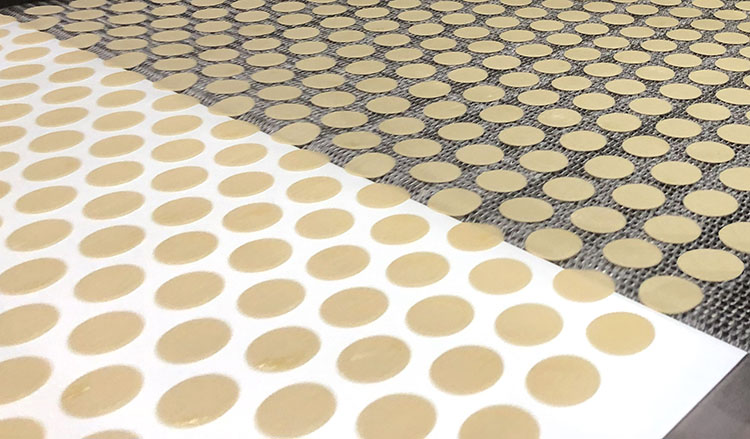

Electricity has been gaining ground as a preferred energy source. RBS has been using electricity for heating for many years; now, it is being applied to larger oven systems and dryers, specialized in baking cookies, crackers and pretzels. For example, RBS describes the Emithermic XE, designed to replace the traditional direct-gas-fired (DGF) oven, as a game-changer for cracker bakers: “DGF cracker ovens are costly, difficult to maintain and often deliver an uneven bake to the product. These problems come from the large number of ribbon burners down the entire length of the oven (up to 300 feet long) that must be maintained and adjusted to deliver consistent heat to the product.” The DGF burners, placed above and below the baking band, supply low- and high-level radiation to heat the product and the traveling baking band in an environment with little to no convection currents. “This unique atmosphere allows baked goods to develop and expand while retaining the necessary moisture to create the product’s flavor and texture profile,” RBS explains.

RBS designed the new Emithermic XE Oven zone to bake via electric radiant heat elements, high radiant Thermatec Panels, and convective heat, eliminating all ribbon burners. It replicates the DGF baking process with a matching oven heat trace, by using a centralized penthouse to circulate and impinge heated air on thermal plates above the product and onto the baking band below the product. High-intensity electric radiant burners then provide the highlighting blisters and colors on the top of the product. On a gas-heated oven, the Emithermic XE zone has two electrically controlled gas-to-air burner systems, down from around 40 burners that can be included in a DGF oven. In this way, the Emithermic XE oven zone also delivers a more balanced heat to the products.

Greater flexibility and control are also built into it, with a humidity-controlled product zone. “The unique feature of the Emithermic XE oven zone is the ability to emulate either the still air environment of a DGF or Cyclothermic oven zone, or the convection air zone of a dryer. The baker can configure and store zone settings of product formulas that require either more humidity for product development or less humidity for product shape setting and drying,” RBS recommends. The flexibility of the Emithermic XE oven zone makes it best positioned as the first third of a tunnel oven of three or more zones.

Retrofitting existing RBS gas-powered ovens to use electricity is a straightforward, simple swap of the penthouses. Electric radiant elements can also be added to any of its ovens, to be used for a toast effect and product coloration before they exit the oven.

Improvements, every day

The latest RBS oven designs include several energy-saving advances, all of them backed by extensive R&D, testing, and data, the company underlines. “Knowing where the heat goes helps RBS design more energy-efficient ovens, something our engineers have been working on for decades,” the specialists explain.

New developments to increase efficiency have also been made to the control systems, which now include downtime software that automatically reduces the fuel consumption of an oven. “The software works by automatically setting the exhaust dampers to a minimum, lowering the belt speed to the slowest setting, and forcing all burners to the minimum firing rate or turning off burners once the cutting system on the production line stops. When additional dough is loaded in the hopper after a shutdown period, the extrusion or sheeting process can trigger the restoration of all production settings,” RBS explains.

Planning for the future

New technologies need to be invented in order to switch to green energy and be more efficient. For example, such advancements would enable ovens to pull the water vapor out of the exhaust air while returning the heat back into the oven. And, rather than heating and re-heating steel belts in tunnel ovens, the belt can return inside the oven and be inductively re-heated just before the product is loaded. “These are all areas where we are working with universities and trade organizations to improve technology which we can implement on new oven designs, RBS shares.

Ovens are undeniably headed into a sustainable future; but, this requirement is only the beginning of the features they need to incorporate. The specialist anticipates ovens with simpler control systems as we move into the future. “As the labor force moves around more freely in the job market, oven controls need to be more intuitive so that new operators can understand how to produce great-tasting products more consistently.”