Dough folding, dough rolling and, most importantly, dough separating: the quality of several product ranges relies on perfect, consistent laminating and sheeting. Achieving the desired number of layers in the exact thickness desired, for the optimum characteristics of each end product, can be just a matter of setting up the right production line correctly.

Production lines for sheeting and laminating dough are usually built around the characteristics of certain product ranges, which are in production at a certain point or are planned to be introduced. However, this equipment can have the flexibility to support changes regarding the look, feel, shape and style of products. Having in mind the ability to provide any conceivable possibilities with minimum physical and financial effort, AMF Bakery Systems is focusing on increasing the flexibility of its sheeting and laminating equipment by having quick changeovers, to minimize downtimes.

“Engineered with the master baker in mind, AMF Bakery Systems’ dough sheeting and laminating technology is developed with a focus on sanitary design to facilitate easy and low-maintenance operation.”

Lex van Houten, Marketing Manager, EMEA and APAC, AMF Bakery Systems

Automation is not just a time- or cost-saving feature for this stage; in line with any other station on the bakery floor, the lack of skilled bakers and operators is a major challenge for dough forming, too. Automated equipment can, by and large, make up for missing staff, or for assigning the team to more meaningful tasks. “This is why our level of automation can help bakeries grow their productivity with our reliable laminating systems by Tromp. We’ve enabled changeovers that do not need any tools to be carried out, we have recipe-driven production programs, so that very little time is required from an operator to run the line,” highlights Lex van Houten, Marketing Manager, EMEA and APAC, AMF Bakery Systems.

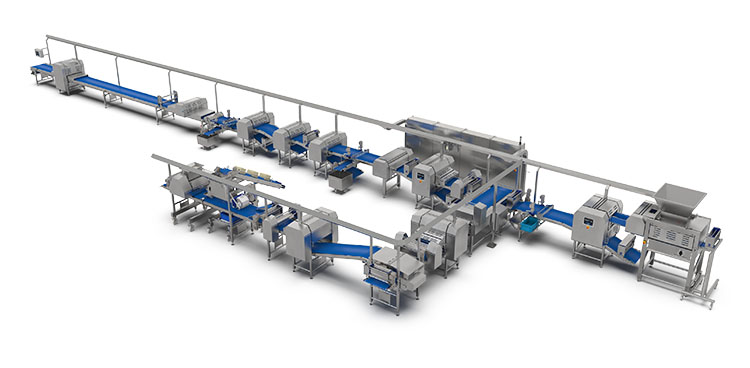

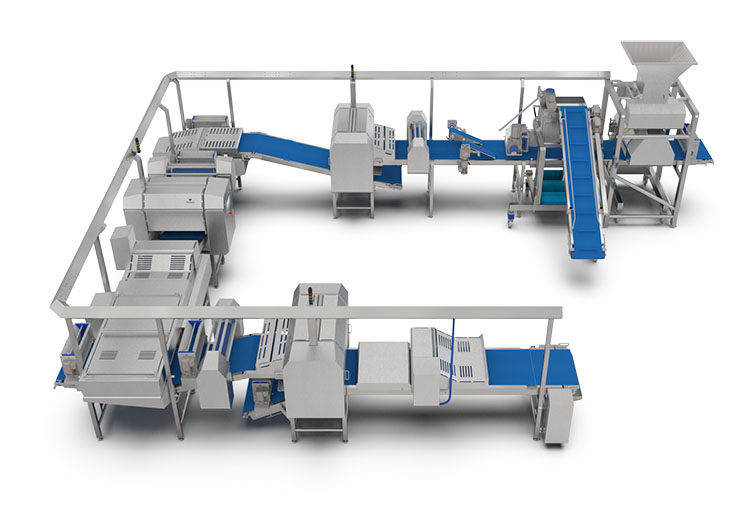

New and improved sheeting and laminating line design: AMF Tromp technology

While challenges related to high (and then higher) production volumes are, to a great extent, under control, today’s to-do list in automated equipment prioritizes food safety, hygienic design, cleanability and sustainability. AMF Tromp laminating and sheeting systems have been updated around these considerations, while maintaining complete process control and high output rates via intuitive recipe management systems for a variety of products, with unique shapes, sizes, decorations and inclusions.

“Engineered with the master baker in mind, AMF Bakery Systems’ dough sheeting and laminating technology is developed with a focus on sanitary design to facilitate easy and low-maintenance operation. The open-frame construction of our dough sheeting equipment allows for full wash-down sanitation, ensuring that hygiene standards are meticulously maintained,” the specialist highlights. At iba 2023, the company showcased its latest advances in hygiene for sheeted bread lines, incorporating a new sanitary design and “revolutionary new features for stress-free, gentle dough sheeting, reduction and handling of highly-hydrated doughs,” the technology specialist described.

With a revised design, flexibility is still a core equipment feature. AMF Tromp is able to provide solutions for virtually any type of product that uses laminated dough, from perennially popular pastries to newly emerging and trending innovations, either croissants, flatbreads, or creative ‘fusion’ concepts.

Cost of ownership has also become increasingly important and will continue to drive technology development, current financial concerns aside. AMF observes a trend toward higher production volumes and corresponding massive factories, a sign that the industry has understood the assignment and is preparing to meet a rising demand for baked goods. Numbers justify the trend: currently, the world population is 8.1 billion, and this will have risen by 73.4 million before the year ends; the world population should reach the 9-billion mark in the next 13 years and is expected to grow to 10 billion by 20571.

“Luckily, healthy food options that are in demand, such as gluten-free, bio, vegan, and many other trends entering the market can also be produced with the same kind of laminating technology that is today used for an already extended range of goods,” van Houten explains. So, these systems can turn profitable quickly. Adding additional features can open the door to even more product choices: a Tromp depositor can be used for various fillings in pastry snacks, sweet or savory, vegan or meat-based.

Laminating, now and later

For practical purposes, laminating lines are usually designed in an L- or U-shape, so that the layer creation and laminating process are set up on the corners of these layouts. It is a setup that works best for the production of many types of laminated dough, including Dutch and French crust. But, a block laminator is also an option, which is usually employed to pre-fabricate blocks of laminated dough, which will be sold as such or are used in the production of pastry products on a different line, the specialist from AMF shares the alternatives available.

Possible setups can vary significantly from one region to the next, each with its specific traditions; AMF automates processes on systems that meet these requirements. While the equipment integrated on an AMF laminating and sheeting line may vary according to specific builds, a fat or butter pump is a mainstay. An extruder is another popular addition, as a method of creating the dough sheet. Dough band-forming solutions adopted may vary, as it will always depend on the products the system will make, as to whether the dough needs to be extruded or sheeted, or whether it contains fat or it needs to be applied and folded into layers. Laminated dough can be created at high speeds and volumes, with as many as 1,000 layers if needed.

Several parameters are critical to achieving optimum results, including the temperature of the bakery, the temperature of the dough itself and the temperature of the fat. The AMF Tromp butter and fat pump is able to maintain product temperature and moisture consistently, with little stress to the fat, ensuring its integrity is maintained while it is applied to the dough. “No piping is used, so cleaning is easier, and no crystallization takes place in the process,” the specialist explains. The pump is built on a C frame so it can easily be wheeled in and out to be integrated into the Tromp (and any other) laminating line.

It can handle a large variety of fats, including margarine and real butter, but also newer alternatives such as vegan, or bio varieties. “We tested this with our ingredient partners from the industry, such as BUNGE, and they are quite happy with the results,” van Houten underlines. When working with butter, using low pressure ensures that the fat remains intact and water will not be separated while it is pumped onto the dough.

The Tromp laminating lines keep the entire process under complete control, by using recipe-driven software and controls. Different automation levels are available, starting from semi-automatic pastry/laminating lines, when a baker is responsible for a small make-up line, scaling up to fully automated systems usually found in high throughput production facilities. For the latter, AMF can build complete systems that include laminating and sheeting processes, starting from mixing through to baking, cooling and freezing.

This technology always has room for growth, both to increase production volumes and product ranges that are made with it. The expansion will be defined case by case, as floor space is also a part of this equation. This aspect is established in the first design conversations, regarding the products that are immediately intended and including any ‘wishlist’ ideas. New features can be added as production expands.