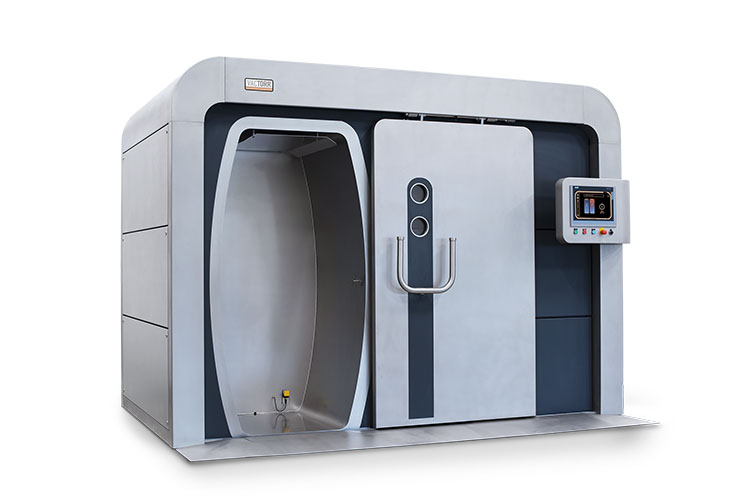

Verhoeven Family of Companies launched its latest technology, its vacuum cooling and baking technology,

remotely. However, equipment testing and adjusting the process to the specifics of the destination environment is key to capturing all the opportunities that vacuum has to offer.

Catalina Mihu: One of the most recent solutions launched by the Verhoeven Family of Companies, the VACTORR Vacuum Cooling and Baking range, was introduced in 2020 in an online event that even included remote unveiling. How has the company adapted to the constraints of the past 3-4 years?

René van Ass: Given our recent theme, symbolizing space and future, looking back gives us a measure of how fast things are developing. With events such as the pandemic, you are forced to think in a different way, to adapt and continue. Since we very much believe that personal contacts and personal business contribute to the success of our company, we staged the event online to launch the VACTORR, despite temporary isolation measures. The machine was ready, the concept was ready. However, we knew that it would be impossible to sell the vacuum cooling and baking concept without testing and live demonstrations. We certainly would not advise our clients to buy it before testing, because seeing and testing is believing, and ultimately, efficiently producing. But, this opportunity was not available during the pandemic. We decided to launch the machine (virtually) and attract attention, with the aim of encouraging potential clients to book appointments and test it for themselves. Testing provides many opportunities, depending on individual situations, ranging from products, recipes, and volumes, to floor space and many other factors that are unique to each bakery.

Being forced to use remote tools meant developing and adopting new technology. One of the biggest changes we made, which is still in practice today, was performing Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT) online. It’s always best to choose the best option: is it necessary for us to be on-site or not? What technology can we use to achieve our goal?

CM: A ‘COVID-proof’ launch event introduced the company’s concept for vacuum technology. What were the development stages of the VACTORR range, including a timeline?

RvA: The technique itself comes from different sectors. By entering the bakery market, the process evolved from a two-dimensional perspective, where the machines were used to cool products down, to a new approach where the technique became a part of the process, as opposed to being used after the manufacturing process. It was first used to cool down vegetables or rice, for example, when the product was ready, in its final form. For us, vacuum technology is used while baking, it is a part of the baking process. Since its role is much more complex than just cooling things down, testing is essential to getting the best results from it.

The challenge is that it was initially introduced and used, in our view, in an overly simplified way – because cooling down is just one of the aspects of the process: in addition, you can improve your product and its shelf life, if the process is carried out correctly. We have been involved in vacuum processing for more than 10 years and VACTORR, our latest range, enhances the identity of our solutions. The launch itself was part of an extended repositioning and rebranding process that would give a face to and put a name on the solutions we propose. Testing and customizing according to specific parameters is not only made for the VACTORR range, but most of our products are custom-designed. But, if you have a challenge in communicating a concept such as vacuum cooling and baking, which is so difficult to convey because of all the individual elements in its successful implementation, it is good to have a practical element encompassing the theory.

The name, ‘VACTORR’, combines ‘vacuum’ and ‘Toricelli’, to pay homage to the Italian physicist and mathematician Evangelista Torricelli, who was the first to demonstrate the existence of vacuum. Through the name, we gave the machines, respectively the solutions, a ‘face’. The first machines were all custom-made, over 10 years ago. Now, there is an entire portfolio in this family of equipment: VACTORR A (for R&D), B (for batch production), C (a continuous baking solution), D (ijko)* and C+ (the custom-made range).

We decided to have the launch event online, first of all, because Martijn van Gruijthuijsen, the Deputy of Economy and Innovation for the Dutch province of Brabant, could not travel to unveil the equipment (because of pandemic travel restrictions), so we developed the means for him to push a button and to introduce them remotely. It was important to prove that it could be done – the machines were connected and the curtain fell to reveal the machine at the touch of a button located in his office, 25 km away from our facility. Technology is part of our portfolio, and it is increasingly using smart tools – including AI as of late, so it was a relevant point for us to make, too.

CM: Speaking of AI and carrying out tasks at a distance, the way we work has changed and fundamentally improved. What changes in the company’s workflow have proved to be significant upgrades and which will remain going forward?

RvA: Monitoring our equipment remotely is very much a part of our service. We will continue to monitor machines and provide service from a distance, as well as carrying out SAT. Integrating such new tools into our daily business and regularly using them effectively is how we can really stand to profit from being able to perform tasks at a distance, as a general observation.

“We will create the environment, tie the knots and put together the entire production unit for the specific project.”

René van Ass, Business Development Officer, Verhoeven Family of Companies

CM: You mentioned rebranding – a big part of it was the repositioning of the organization with the introduction of the Verhoeven Bakery Equipment Family, in July 2020. Could you explain the current structure?

RvA: The Verhoeven Bakery Equipment Family is part of the Verhoeven Family of Companies, which consists of two divisions: bakery equipment and internal transport – material handling for a variety of industries. Over the years, we have extended our focus to the bakery market.

Of the group’s four labels, which come from mergers and acquisitions, BVT was the first one to join the Verhoeven company, coming from the Netherlands. NewCap was then formed, incorporating a part of Capway. Next came Vacuum Cooling and Baking Solutions, joining forces with Patrick Duss. Bakepack, our fourth label, was developed in-house. There was some overlap between the specialties of each brand and to avoid any confusion regarding who does what, we felt the need to present ourselves more as an entity. It is important to show that we work together, and we belong together. It is vital to know which label does what, of course; but, it’s even more important to show that we are able to provide clients with many solutions for several process steps, through our various labels, and that there is synergy between them. This synergy comes from working together, being very straightforward and open to each other. As a family, we work together to provide a total solution. To a certain extent, there is some overlap between the solutions the companies provide, between Newcap and BVT, for example. But, it is by choice, to allow us to diversify our offers. Together, as Verhoeven Bakery Equipment Family, we are able to provide a huge variety of solutions. Discarding valuable names and the reputation behind them was not the best solution for us, so we preserved the brands as members of the Verhoeven family. We built a ‘roof’ under which these brands could work and benefit from the synergies between them.

In this way, we can provide turnkey solutions, complete projects, which is what makes our company stand out. We can flexibly include machines from a wide range of our equipment and, if necessary, solutions from an external party. This is likely soon to become the norm, in our view, as product lines are becoming more and more complicated to incorporate new-generation technologies such as AI features, which leads to challenges that sometimes cannot be solved from the client’s side alone. After all, they are specialized in baking, purchasing and the economics of the business, and not necessarily in building a line. This is where we can help, by providing whole solutions integrating ovens, instead of standalone labels.

Verhoeven means complete solutions

CM: Speaking about building and refining an identity, are you focusing more on the Verhoeven name, or communicating its brands? What would you like the new identity to be known as?

RvA: The Family positioning is the future. We know that this transition takes time. People are used to labels, and we do acknowledge that labels represent values, which we are not throwing away. It is a matter of people getting used to the new image, which, in bakery, is not always the fastest process. It will take some time to build on this. And until it is completely clear that BVT is part of the Verhoeven Family, we will still work with both ways of communication, while reinforcing the message that it is all just one family.

Another reason for the positioning is that new developments within the organization, or a new specialization with its separate company name, they could be mistakenly perceived as an individual company instead of showcasing the full power of the entire company.

“Packaging does not start at the end of the production flow, it starts at the beginning for us. We look for ways to integrate certain elements in the production process to be able to get the final product to leave the factory in the best possible conditions. ”

René van Ass, Business Development Officer, Verhoeven Family of Companies

CM: BVT also coined its recognizable and commonly used abbreviation. Are you proposing a new abbreviation for the Verhoeven Bakery Equipment Family?

RvA: I agree, and this is a challenge. Not everyone might be open to a new abbreviation, and we don’t use one ourselves. We shorten the name to ‘Verhoeven’, which is enough of a challenge in itself, perhaps, as a Dutch name.

CM: How do the companies within the Verhoeven Family – BVT, NewCap, Vacuum, Bakepack work together now, on day-to-day operations and on developing new solutions? Please illustrate.

RvA: Looking at Bakepack, for example, which specializes in packaging, it also integrates the other solutions; packaging does not start at the end of the production flow, it starts at the beginning for us. Packaging may handle the finished products and prepare them to be shipped out, but we already have it in mind during the production process, for stages where certain things can be set in place that will be vital to final packaging. So, packaging isn’t considered as the end stage, but rather looked at as a whole and how certain elements can be integrated in the production process to ensure the final product leaves the factory in the best possible conditions. Many aspects are considered here, including shelf life.

The Verhoeven Family of Companies

1. BVT Dough Process Solutions

2. NewCap Industrial Handling Solutions

3. Vacuum Cooling and Baking Solutions

4. Bakepack End of Line Solutions

CM: What can each label bring to an integrated, complete offer? How do the Verhoeven companies build complete projects together?

RvA: It depends on which development the client aiming for: is it for a full project, or is it because they have heard about the vacuum cooling and baking technology, and they know that we are able to integrate it into existing lines? Is their goal to expand their capacity in the existing facility with a new line, or to build a new factory? To answer such different requests, there is a constant flow of communication within the company. This is why we only offer tailor-made solutions, in which all our labels must play a certain role. We are not on the market to simply provide ‘just’ ovens; there is, sometimes, an emotional component to choosing an oven. This should be honored, but should not limit the baker, as we can support them by creating a whole line around their oven of choice. This is where our strength lies as a combination of labels.

We are able to create complete solutions, including parts that are not made by us, when they are needed. In this case, we will create the environment, tie the knots and put together the entire production unit for the specific project. This type of service is becoming more important, we believe, as the technology is becoming increasingly more complex.

CM: You made an interesting reference, mentioning Patrick Duss. With the rights transfer from Aston Foods, the brand name of one of the pioneering organizations in Vacuum Cooling was reunited with its founder, Patrick Duss, in 2019. What is the timeline of developments regarding this innovative technology, that culminated with this move?

RvA: This was more of a defensive move on our part, in the scenario that the brand would keep the name and develop in a new direction. We wanted to prevent misconceptions in that sense, had the company re-entered the market from a new direction but under the same name. In 2019, we were able to acquire the intellectual property of the Aston name, so we could prevent it from going on a path we did not want it to take.

The Sky is Not the Limit

CM: Moving on to a topic you like, considering the futuristic concept of Verhoeven’s iba booth in 2023: how will the new structure influence developing solutions for the baking industry going forward?

RvA: Good question! Our R&D and our engineering have always been one department, and not four separate ones, corresponding to each brand. Of course, there are people with different specialization fields, but they are part of a unitary team. Our R&D is one department. It would be a waste to have it otherwise, because there is a strong

interaction between labels. And, at the end of the day, it is the same client we are talking about, so it would be a waste of energy and functionality to have this department fractured. It already was the case, before our rebranding. We are now simply communicating the way it’s always been, an entity.

“We are not on the market to simply provide ‘just’ ovens; there is, sometimes an emotional component to choosing an oven. We can support clients by creating a whole line around the oven of choice.”

René van Ass, Business Development Officer, Verhoeven Family of Companies

CM: So, the rebranding was the last step, and the company was already functioning as a family?

RvA: Exactly. It is possible that a new or existing label could be added, and the same structure will be preserved.

CM: That is an interesting perspective. What would

Verhoeven consider an interesting focus for an additional label, seeing as the existing four complement each other?

RvA: That depends on how the market develops. One possible scenario could be growing an existing brand, or innovating something new. Let’s take vacuum technology for an example – if the concept was mentioned 20 years ago, it would not seem to fit the baking process. We think that there are still a lot of new innovations out there to gain from. Recycling, for instance, is an aspect that should be a part of a new production line. Adding new techniques will definitely be a focus for the future.

A dedicated group is studying trends internally, focusing on the bakery of the future. This is partly the answer to what comes next after our demonstration in Munich, where our motto was, ‘The Sky is Not the Limit’. Then, we introduced our focus for inspiration from and for space programs. We are nowhere near the limit, and we may never reach it. It’s an ongoing journey.

What does the future hold? With all the developments in our society, we sometimes have to rethink what we do and find solutions to the new challenges we face. Sustainability, establishing better connections between production and the market, growing an ever-wider portfolio – there are many challenges we can try to include in the solutions we offer. In that sense, I think there are many challenges for us in the future that could be potentially solved by either developing a new label, acquiring one, or joining forces with another company. So, the Sky is Not the Limit! We’ve only just begun.

CM: What are you focusing on for innovation?

RvA: The products are changing. We see a lot of fusion concepts and hybrid creations now; in the past, bread was bread. We were recently testing new products that can certainly not be defined as bread. This is a challenge as well, determining how food develops, together with consumer preferences. Are we going to seek more variety? I think so. We could be slowly heading towards a completely new fusion style of eating, worldwide. Entirely new products are being developed and are increasingly entering the markets. Bakery also will expand its reach outside of the classic understanding of the industry, and go more into food

development. This is going to happen.

CM: Is there a certain geographical market that you are specifically focusing on, or one that could be the source of such innovative types of products?

RvA: The global market is and will remain our market. The majority of our turnover comes from non-domestic clients. We love innovation, so we will support new developments, no matter where they emerge, from the Midde East to

Africa and beyond.

CM: And how is R&D revolving around the needs of smaller operations as well as those of large industrial bakeries?

RvA: Innovation is key to solving many challenges. Vacuum cooling and baking could help smaller operations increase their output with the same amount of people. For bigger organizations, it’s worth remembering that they are still people-run businesses. The bakery industry is an old one – we may tend to forget that some things that are part of our daily lives are very important. It’s not always about figures and statistics alone. In that sense, bigger organizations can learn from smaller ones.

The VACTORR family is a good example of solutions that can fit both small and big operations. They are completely scalable, and the technology can be used in any production environment. For us, it is very important to design them this way. All in all, it is down to the people in the organizations and the technology that can support them.