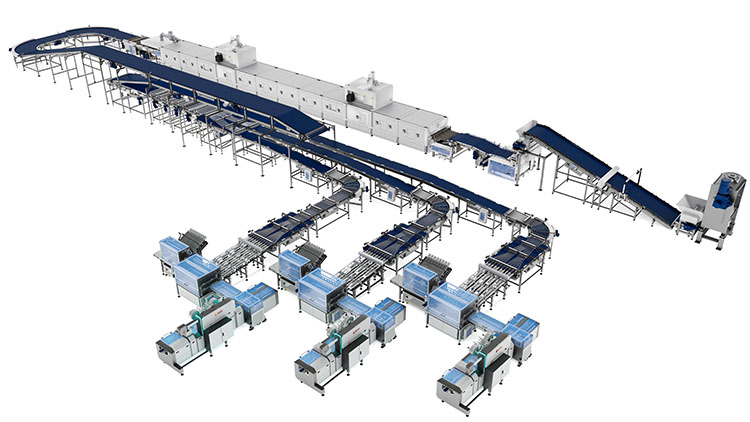

Designing the turnkey line that fits best with a given environment throughout each process step also starts with people: the design team tasked with bringing together only the perfect pieces of the puzzle that will become a new line.

PART I Automated production lines are the solution to optimizing production and optimally allocating resources, including a critical one: the…

PART I Soft dough biscuits are among the popular snacking choices worldwide. Their success comes, in no small part, from…

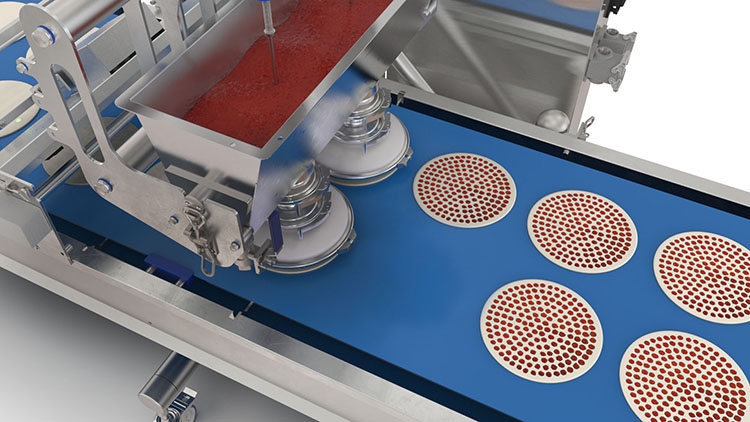

For industrial production, pizza lines are made to welcome any variations required. Accurate processes are a must for these flexible lines.

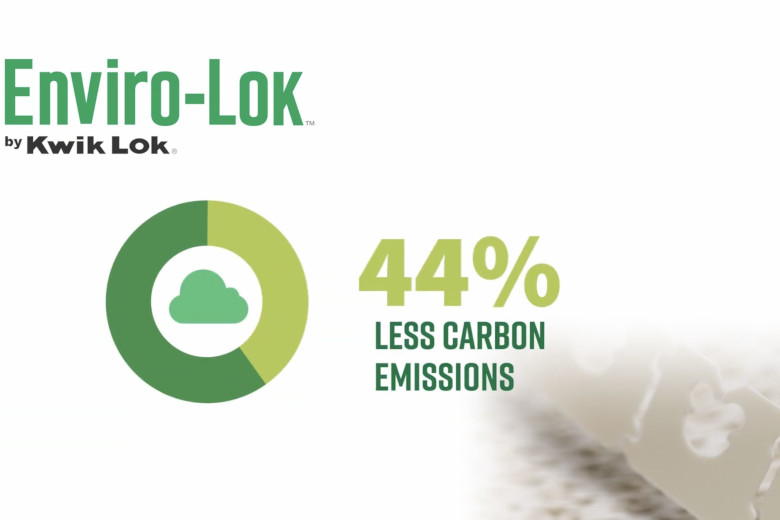

Widely different concepts, approaches and methods lead to advancing sustainability throughout a company’s operations. For Kwik Lok, sustainable materials used in packaging closures are the immediately visible result of this mindset. And, this priority also influences the process.

UPM Specialty Papers, Lantmännen Unibake and Adara teamed up to create a new fiber-based packaging that replaces plastic bags as primary packaging for frozen baked goods. To minimize the use of fossil-based materials, plastic bags were eliminated by using UPM Asendo barrier paper as an inner liner in the corrugated cardboard box.

At home or at the restaurant, for lunch, office parties, or even for breakfast, ordered in person or online, the…

Kwik Lok announced the launch of its latest bag closure designed for sustainability. The Enviro-Lok is a polypropylene bag closure that is made to keep products safe and fresh, while also delivering a better potential for recycling.

David Wagstaff, the managing director of St Pierre Groupe, discusses how the cost-of-living crisis is impacting the industry. He also…

On popular demand, the Shanghai World of Packaging (swop) will be held every year from 2024. Even before the start of swop 2023, it was clear that the trade fair will already be held again in 2024, Messe Dusseldorf explains, to match the growing demand from exhibitors and visitors.