The Western European market has grown by 8.6% between 2022 and 20231, the largest growth rate worldwide. Next, APAC was also forecast to grow by 8.3% last year, while the pizza industry in Eastern Europe showed similar growth during this period, ranking third (7.6%).

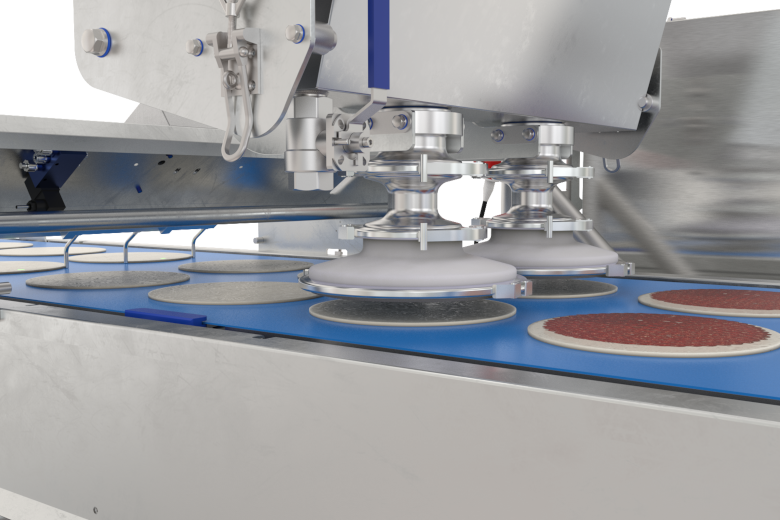

Preparing pizza implies making and forming dough bases, onto which sauce and toppings are added. With each stage, there are opportunities to diversify the final product. For industrial production, pizza lines are made to welcome any variations required. Accurate processes are a must for these flexible lines.

AMF Bakery Systems turnkey lines

AMF designs an extensive range of equipment for pizza dough preparation. The best equipment lineup is determined to fit specific manufacturing requirements and various types of pizza, in terms of recipe, taste, bite, shelf life and type – either fresh or frozen. “This determines what kind of dough you produce and use for pizza; ‘it’s all in the dough’ is a well-known slogan” in this regard, AMF explains. Starting from the types of dough that will be used, AMF specialists are testing the recipes to match them to the best technology, starting with horizontal and continuous mixers for dough preparation. “Dough handling is the base of our design philosophy, based on what our customers want,” AMF highlights. Then, the process is key to lining up the most suitable equipment for a wide variety of products – in terms of production capacity, product sizes and varieties, as well as processing sequences, for either dough balls of sheeted pizza for retail, QSRs, baking fresh, or bake-off.

Flexibility can be understood in several ways: lines can be built to be dedicated to a certain type of product, with variations in size only – meaning cutting blade changes – or to accommodate entirely different products. In this case, production can be set up to skip a certain step, change some parts, or wheel in another AMF Tromp unit entirely, for changeovers that only take a few minutes so that production can quickly resume. “There are even examples of lines using two ovens on one sheeting line, to make two completely different end products and pizza bases. The possibilities are endless,” AMF illustrates.

AMF pizza and pinsa lines process different kinds of dough, from frozen and cut to molded, or pressed – all on the same line. For the dough mixing (AMF Fusion ensures gentle mixing) and forming stage, there are two options to choose from: making dough balls (which can also be pressed in a pan) or dough sheets, which can either be made via a low-stress process or extrusion, depending on the type of dough.

The right setup for the product

The specialist in sheeting lines can offer many options for this process, to achieve a flexible setup for the desired types of pizza. “Any variations, from American style, Italian style, pressed pizza base (for a certain bite), or just long fermented and stone floor baked pizza bases with a lot of ‘bubbles’, they can all be made on the AMF Tromp pizza systems and sheeting lines,” AMF explains. From semi-automated to high-end, high-speed lines that are completely automated, AMF sheeting systems can make over 100,000 pizzas, flatbreads and pinsas per hour.

For proofing, the environment and the climate are crucial, in line with the recipe and the ingredients – if these have the same characteristics, then the sheeting and proofing equipment will produce consistent results. For dough proofing, fermentation rooms can be provided, where dough rests before dividing. Belt proofers can handle the entire dough band and work great for pre-proofing and can be used for final proofing, too (cascade proofing), while multideck belt proofers can be used to proof cut pieces and products.

The baking process with its corresponding AMF Den Boer technology is determined by the style of the end product – either with a softer crust, such as the varieties preferred in Asia, or a crispy crust in Italy. American-style crust, by comparison, is thicker. Everything else also contributes to selecting the correct baking parameters, from the pizza style to the toppings, or whether it is par-baked or fully baked, for example. Carriers are also taken into consideration, whether the pizza will be baked on a stone floor, a steel belt, mesh belt, or in pans. To perfect the process when working with so many variables in automated production, AMF’s Sustainable Oven Service supports anything from oven settings to feedback based on oven data (analyzed by AI).

After baking, spiral coolers and freezers, or ambient coolers bring the product to the temperature needed for packaging. “Here, time is important, as is productivity, and gradually lowering the product’s temperature, to preserve its quality,” AMF points out. For this stage, it uses direct drive technology for improved product handling, less ‘shaking’ that could damage the product, less energy needed, less maintenance and better results.

For handling, AMF Workhorse offers multiple solutions, including palletizing, crate/box handling and packaging using robots. In this way, AMF can “Create fully automated lines, with automated mixing and fermentation at the beginning of the line, automated pan handling, cleaning and storage systems at the end of the line, and handling boxes and pallets ready for shipment.”

Latest technology upgrades on an AMF pizza line

- Smart applicator topping

- Sustainable Oven Service (SOS)

- Mixing, Dough Guardian (patented process control technology)

- Hybrid systems with hydrogen or electric energy sources

This article is part of an extended feature published in Baking+Biscuit International, issue 5 – 2023.

Photos: AMF Bakery Systems