Anton Paar brings quality control solutions to iba ‘25

At iba 2025, Anton Paar exhibits at iba with the theme ‘Advanced Quality Control, focusing on solutions for quality control in the baking, food and ingredient industries.

At iba 2025, Anton Paar exhibits at iba with the theme ‘Advanced Quality Control, focusing on solutions for quality control in the baking, food and ingredient industries.

Automated inspection systems are able to guarantee top product quality and safety – no exceptions allowed. In-line vision inspection technologies comprehensively inspect 100% of the products throughout the entire manufacturing process.

An internationally recognized method exists to characterize the water absorption capacity with ease and efficiency.

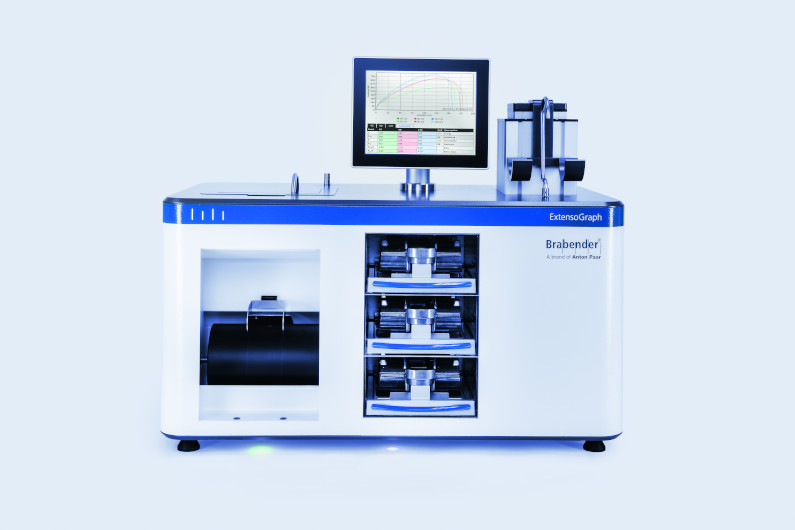

Brabender further developed its Farinograph to determine the water absorption capacity of flour and the rheological properties of dough, launching a new version of the device on the market that uses Artificial Intelligence to predict measurement curves.

KPM Analytics showcases solutions that meet growing trends such as automated product inspection, process control achieved with vision inspection, processing whole wheat/high-fiber products, at-line dough quality analysis, and ingredient quality control.

Wooden Bakery of Lebanon has maintained the product quality its customers are accustomed to, throughout several, sometimes overlapping challenges over the years. To cope with the latest struggles due to material availability, the use of flour and dough rheology technologies has helped the business manage flour quality.

KPM Analytics acquired Smart Vision Works, a company specializing in artificial intelligence (AI) providing computer vision systems for agriculture and food industries. Smart Vision Works is well known for its AI and edge computing technologies, used to sort products and detect foreign materials in the food production processes.

Improving the profiles of baked goods benefits from gaining a deeper understanding of all the process steps and reactions behind them. Combining functional and molecular flour analytics will establish a comprehensive picture of the grain, and help to achieve better baking results.

Combining functional and molecular flour analytics will establish a comprehensive picture of the grain, and help to achieve better baking results.

Smart devices are quickly becoming an indispensable part of life inside the baking shop as they are on the outside. For in-store ovens, smart tools are being developed to make them more efficient and easier to operate for consistent results.

As gluten-free bakery is decisively increasing its foothold into the mainstream market, growing by about 25% each year, research seeks to improve product taste, texture and nutritional profiles.

In the industrial baking of any type of bread, and a multitude of other product ranges, tunnel ovens are the giants of large-volume, continuous baking, for which efficiency is a must.