When the stakes are high: Forbo

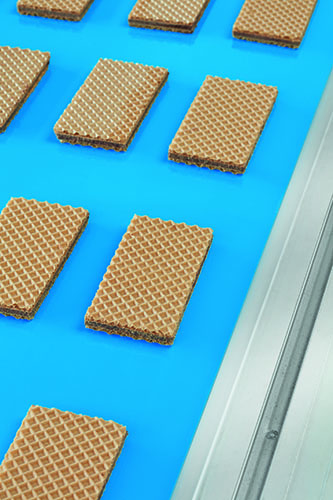

With the ‘Siegling Fullsan’ product range, Forbo Movement Systems has launched new homogeneous conveyor and processing belts made of TPU (thermoplastic polyurethane) particularly for hygiene-sensitive applications.

With the ‘Siegling Fullsan’ product range, Forbo Movement Systems has launched new homogeneous conveyor and processing belts made of TPU (thermoplastic polyurethane) particularly for hygiene-sensitive applications.

Energy efficiency may be just part of the equation when selecting a type of belt, but it is an increasingly important one given the dramatic rise in energy costs that the world is currently experiencing.

Reliable product transfer between processes is essential to maintaining the rhythm in production sequences, with continuous, automated adjustments. To optimize efficiency in industrial baking, everything is riding on conveyor systems.

Ashworth will launch a new smart solution at IBIE this year, the Smart Oven monitoring system, joining the Smart Spiral in this range.

Koenig has recently developed a scoring unit powered by Artificial Intelligence, with the help of 3D scanners and cameras.

Automated scoring systems consistently execute cuts, using conventional cutting, ultrasonic cutting, or waterjet technology.

Conveyor systems work under demanding conditions in bakeries. Maintaining them in top shape is the first step to efficiency in production; upgrades will then guarantee optimum performance in handling processes for truly competitive-level manufacturing.

Replicating traditional methods of preparing buns, bagels and rolls on an industrial scale is a task with an extensive list of challenges, to achieve high-volume, consistent results. Flexibility and innovation joined in dedicated production lines help provide the answers for endless product variations.

Scoring is a process that requires skill and shows the baker’s experience when done manually. Alternatively, as labor is becoming harder to find (and then keep), robots can efficiently take over the task; they will never need to stop and will perform constantly over time.

Ashworth provides recommendations in terms of materials, design, and engineering. The choice will be the result of an extensive checklist and case-by-case analysis.

The COMJET with the WP Robot promises professional lye application combined with a robotic cutting plant.

At the iba trade fair last September, Ashworth Bros. Inc. unveiled a new, patented solution for spiral conveyor systems called PosiDrive Spiral™.