DIOSNA introduces IoT solution

DIOSNA launched a new IoT solution for dough production. The system monitors the condition and product quality through live data. It can be accessed remotely.

DIOSNA launched a new IoT solution for dough production. The system monitors the condition and product quality through live data. It can be accessed remotely.

Koenig has recently developed a scoring unit powered by Artificial Intelligence, with the help of 3D scanners and cameras.

The König Group expands as it took over Vulganus Oy in July. The traditional company, based in Nastola, Finland, specializes in tailor-made spiral systems for the bakery and food industry.

Automated scoring systems consistently execute cuts, using conventional cutting, ultrasonic cutting, or waterjet technology.

Innovation in Artificial Intelligence algorithms can be applied to baking processes for improved results.

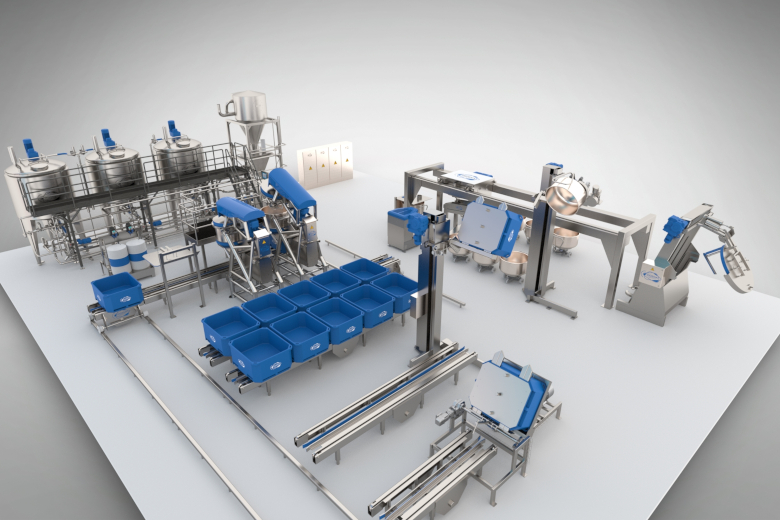

Replicating traditional methods of preparing buns, bagels and rolls on an industrial scale is a task with an extensive list of challenges, to achieve high-volume, consistent results. Flexibility and innovation joined in dedicated production lines help provide the answers for endless product variations.

A versatile piece of equipment that can be used for all processes requiring controlled temperatures is the spiral. For this technology, Ashworth developed the SmartSpiral® Monitoring System, an application that provides real-time monitoring of multiple spirals, even over different facilities.

Scoring is a process that requires skill and shows the baker’s experience when done manually. Alternatively, as labor is becoming harder to find (and then keep), robots can efficiently take over the task; they will never need to stop and will perform constantly over time.

The shortest way to efficiency in proofing, cooling, freezing, or baking is sometimes a spiral.

Kaak lines are used both for dough balls, which can be stored chilled until they are shaped in production or in the store for some days, as well as for complete lines that either press dough portions to the base using the hot or cold process or from the ‘cut out’ of a dough sheet.

Mixing up label rolls in production is every food manufacturer’s nightmare. Visual inspection of the products is time- consuming, personnel-intensive, and still carries risks.

The COMJET with the WP Robot promises professional lye application combined with a robotic cutting plant.