Ishida launches new solutions at interpack

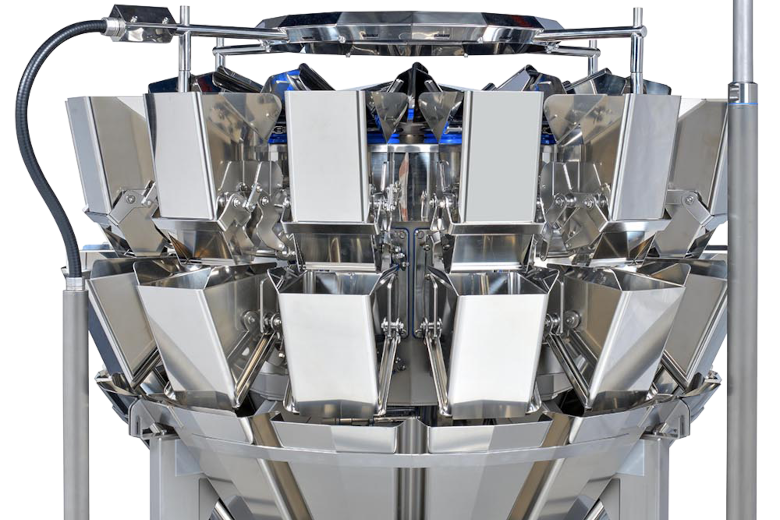

Ishida will bring 40 pieces of equipment to display at the trade fair, focusing on four areas: weighing technology, quality control solutions and ‘end-to-end’ packing line solutions.

Ishida will bring 40 pieces of equipment to display at the trade fair, focusing on four areas: weighing technology, quality control solutions and ‘end-to-end’ packing line solutions.

At interpack, Syntegon is presenting a flexible line concept for packaging sensitive baked goods – from product distribution to case packaging. The seamlessly integrated packaging system comes with several novelties.

Sweet or savory, pies are a perennial favorite among consumers. Highly specialized production lines are developed to ensure production meets quantity as well as quality needs, efficiently.

Packaging affects the state of the product throughout the supply chain. Identifying the best packaging process and materials ensures all types of baked goods make it from plant to table, exactly as intended.

Syntegon presents flexible systems for cookies and bars, an Innovative Intelligent Direct Handling system that offers format flexibility for cookies and crackers, a high-speed bar system for maximum efficiency with new wireless HMI, and sustainable packaging for cookies and bars made of paper and mono-material.

Some of the highlights at Schubert’s stand include cobots for the rapid feeding of different packaging components on a line and an entirely new, efficient, resource-saving feeding system for carton blanks.

A first-of-its-kind World Health Organization (WHO) Global report on sodium intake reduction shows that the world is off-track to achieve its global target of reducing sodium intake by 30% by 2025. Sodium is an essential nutrient, but, it increases the risk of heart disease, stroke and premature death when eaten in excess.

The beginnings of pinsa making go all the way back to the Roman Empire. A fresh new take on the Roman pinsa is now rising to the top among consumer favorites.

From viennoiserie to Danish pastry, and any number of hybrid, new creations, laminated dough is the path to the sought-after airy, light layers.

Precision and consistency are required to turn blocks of dough into thin, delicate sheets. The big challenge lies in the correct distribution of the dough reduction steps while avoiding any unwanted tension in the dough. Inconsistencies in the reduction steps will significantly impact the structure of the final product.

Pizza is one of the most popular foods worldwide, and various plant constructors offer industrial pizza lines. Here is a small overview of the manufacturers and methods.

Mecatherm has developed a new dough divider, the M-NS, presented for the first time at the 2018 iba trade fair.