Continuous baking: Go with the flow!

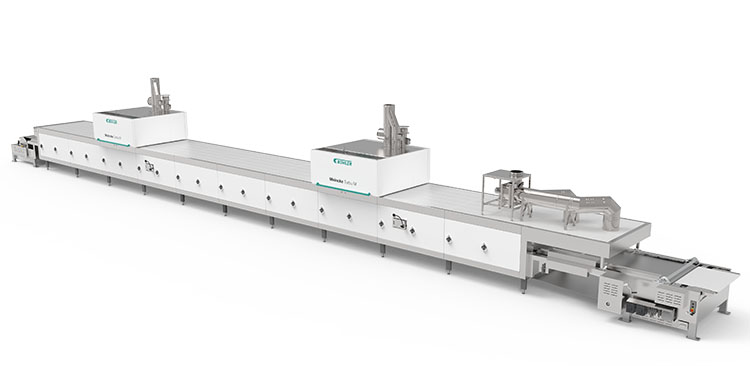

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

MULTIVAC Group acquired an 80% majority stake in Italianpack S.p.A., a manufacturer of automatic and semi-automatic packaging machines headquartered in Como, Italy. Italianpack will be incorporated into the MULTIVAC organization as a new business unit under the leadership of Tomaso Petrini, CEO of Italianpack.

With BVT’s turnkey line, product variety extends beyond sweet and savory pies, which by themselves make up for a diverse product range, to begin with. The fully automated Pieline can handle all types of pies, tarts and cakes.

The automated line designed by AMF Tromp can flexibly support a wide range of pies, either savory or sweet, in a baking tray, in foils, or in paper cups. They can bake the pie shells only, pies with the top opened or closed and pies with or without a lattice decoration. For (pre-)baking the pies, AMF recommends a Den Boer Multibake tunnel oven with impingement heating or a direct-fired system.

For industrial production, pizza lines are made to welcome any variations required. Accurate processes are a must for these flexible lines.

Royal Smilde is known for its rich diversity of sweet and savory baked creations. Either sold under its own labels, through collaborations, or as private labels, the products made by the Dutch bakery are in growing demand worldwide. A very flexible production line helped them increase production volumes, built by AMF Bakery Systems (Tromp). Particular care was given to automating apple turnover production, namely – dough folding into a triangle.

BAKON Food Equipment announced a new operating system for their machinery. It allows operators to control complex production systems through an intuitive dashboard.

The Dutch ‘silo to truck’ solutions manufacturer develops production lines for all kinds of freestanding bread, with a capacity of around 7,500 kg/h, depending on the production process, type of end products and available space.

This year, the French specialist focuses on solutions for energy efficiency, the new, easy-to-clean M-DAN oven and new digital solutions for industrial performance. MECATHERM is launching the new M-DAN Oven, with an improved hygienic design that includes wash-down capability.

The COMJET with the WP Robot promises professional lye application combined with a robotic cutting plant.