Continuous baking: Go with the flow!

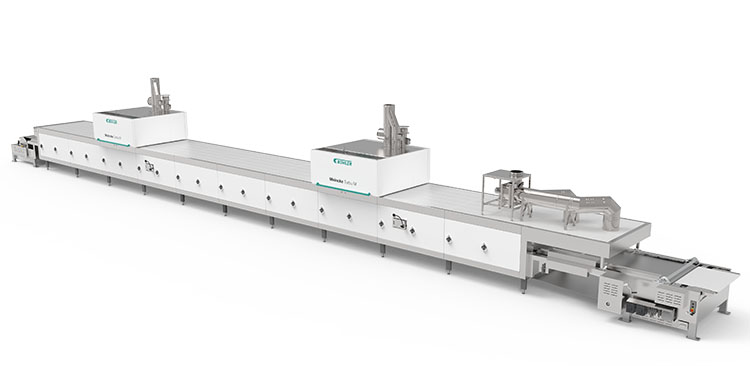

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

Artificial intelligence (AI) in manufacturing is no longer a fascinating idea – it is already here and accelerating quickly throughout many industries, especially in the baking industry. Several reasons are fueling this revolution.

A steadily growing appetite for pizza is met with interesting new offerings, including plant-based, premium, and limited-edition launches. Technology meeting these trends is a must for efficient pizza baking.

The APEX Mini Combo BDR Bread and Bun System by AMF Flex won this year’s ‘Innovation for Growth’ award at Bakery China. AMF Bakery Systems (AMF) developed this system focusing on automating processes and improving efficiency as well as efficiency in the production facility.

The automated line designed by AMF Tromp can flexibly support a wide range of pies, either savory or sweet, in a baking tray, in foils, or in paper cups. They can bake the pie shells only, pies with the top opened or closed and pies with or without a lattice decoration. For (pre-)baking the pies, AMF recommends a Den Boer Multibake tunnel oven with impingement heating or a direct-fired system.

Automated inspection systems are able to guarantee top product quality and safety – no exceptions allowed. In-line vision inspection technologies comprehensively inspect 100% of the products throughout the entire manufacturing process.

For industrial production, pizza lines are made to welcome any variations required. Accurate processes are a must for these flexible lines.

Royal Smilde is known for its rich diversity of sweet and savory baked creations. Either sold under its own labels, through collaborations, or as private labels, the products made by the Dutch bakery are in growing demand worldwide. A very flexible production line helped them increase production volumes, built by AMF Bakery Systems (Tromp). Particular care was given to automating apple turnover production, namely – dough folding into a triangle.

‘Artisan’ and ‘premium’ are often used interchangeably when referring to bread. To Koenig, ‘premium’ products are crusty breads, with complex flavor and a chewy crumb.

The Dutch ‘silo to truck’ solutions manufacturer develops production lines for all kinds of freestanding bread, with a capacity of around 7,500 kg/h, depending on the production process, type of end products and available space.

Sweet or savory, pies are a perennial favorite among consumers. Highly specialized production lines are developed to ensure production meets quantity as well as quality needs, efficiently.

This year, the French specialist focuses on solutions for energy efficiency, the new, easy-to-clean M-DAN oven and new digital solutions for industrial performance. MECATHERM is launching the new M-DAN Oven, with an improved hygienic design that includes wash-down capability.