DIOSNA introduces IoT solution

DIOSNA launched a new IoT solution for dough production. The system monitors the condition and product quality through live data. It can be accessed remotely.

DIOSNA launched a new IoT solution for dough production. The system monitors the condition and product quality through live data. It can be accessed remotely.

Innovation in Artificial Intelligence algorithms can be applied to baking processes for improved results.

A versatile piece of equipment that can be used for all processes requiring controlled temperatures is the spiral. For this technology, Ashworth developed the SmartSpiral® Monitoring System, an application that provides real-time monitoring of multiple spirals, even over different facilities.

Mixing up label rolls in production is every food manufacturer’s nightmare. Visual inspection of the products is time- consuming, personnel-intensive, and still carries risks.

Minebea Intec, Hamburg, the German part of MinebeaMitsumi, a globally operating group (annual sales revenues EUR 7.3 billion), specializes in

New digital technology provides a better way to measure humidity in proofers, oven, dryers and cooling tunnels.

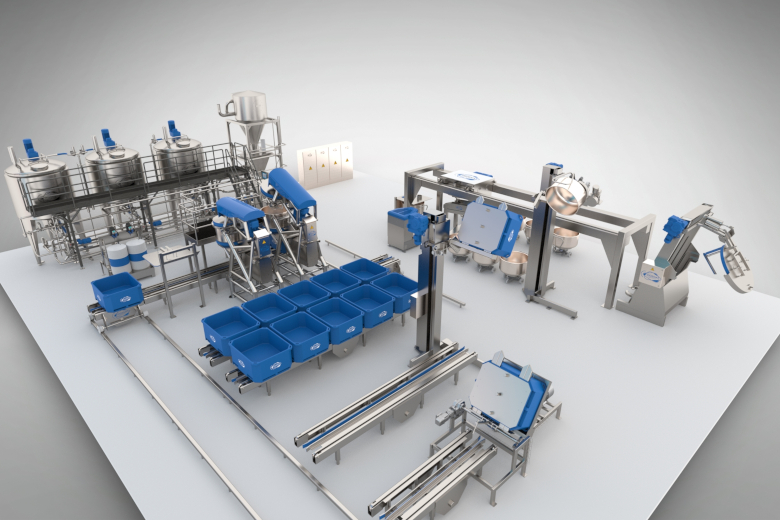

Bakers weigh out their raw materials by the shovelful – that may have been true in earlier centuries, but nowadays surveillance authorities and raw materials prices both equally ensure that weighing, monitoring and subsequent analyses accompany the entire production process.

Ishida Europe specializes in the fields of weighing, packaging, and quality control. The company is market launching a number of innovations in 2018.