RBS launches ambient cooling conveyor for cracker systems

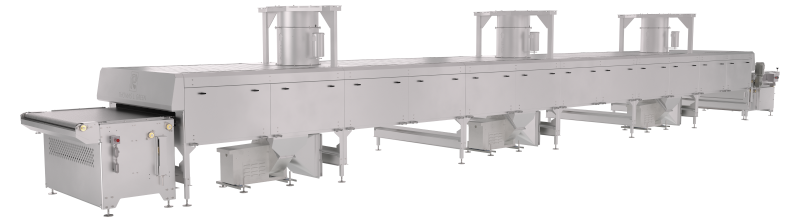

Reading Bakery Systems (RBS) introduced a new ambient cooling conveyor, with increased efficiency in cooling crackers before entering packaging in a more‐compact footprint.

Reading Bakery Systems (RBS) introduced a new ambient cooling conveyor, with increased efficiency in cooling crackers before entering packaging in a more‐compact footprint.

IPCO developed a cooling tunnel with improved energy efficiency provided by a newly designed airflow system, for use in the confectionery and bakery industries.

As crackers exit the oven, the cooling process is important to guarantee product quality and a long shelf life. A gentle cooling process will ensure the delicate product’s integrity until it is ready to be consumed.

Consumers are not just hungry for any cakes, but are seeking diversity and sensory experiences in their choices. The technology behind baking such options needs more flexibility.

Advancements in proofing technology are focusing on obtaining the best possible product and on flexibility for all possible process needs.

In industrial bagel manufacturing, the biggest challenge is fitting the production line in the available space while meeting individual recipe and process demands. Due to space constraints, certain modules can be considered optional, while others are highly recommended when customizing a line to specific requirements.

The shortest way to efficiency in proofing, cooling, freezing, or baking is sometimes a spiral.

Flexibility is the top priority when manufacturing cupcakes and muffins as well, as highlighted by the Unifiller Europe Flexline, one of the favorites among the Linxis Group specialist’s customers. This line can first be used for depositing muffin and cupcake batters, and (after baking) for the injection of fillings or cupcake decorations.

Mecatherm, French manufacturer of industrial ovens and production lines, has signed a partnership with American ABI Ltd, a specialist in bagel makeup equipment. Together they are planning to market an industrial bagel line. baking+biscuit international investigates further.

DEBAG’s blast freezer works in a temperature range from – 30 to + 5 °C and is suitable for cooling and freezing of products hot from the oven as well as raw and fully proofed dough pieces.

Small baked goods production: Innovative dough dividing, forming and depositing in a single step with the FS 520 forming system.

For the production of small pastries, the plant manufacturer Handtmann offers solutions for fully automatic production.