Automating packaging and coding not only streamlines the process but also checks all of the boxes – efficiency and transparency, material traceability and sustainability.

Labor challenges have led Europe to be a step ahead in automating the packaging process according to Kwik Lok. Still, there is room for expansion in automation in Europe and beyond, especially since it encompasses proudly diverse markets.

Some traditional bakeries, for example, are still finding their footing in scaling the automation of their operations, packaging included.

In addition to eliminating the need for manual labor, automation also benefits predictive maintenance planning. Bakeries looking to improve their packaging practices are adopting fully automated packaging lines for their speed, convenience and efficiency. To optimize this step that truly adds the finishing touch to bakery products, the workflow throughout the process chain must work well. Packaging solutions such as those provided by Kwik Lok bring important benefits to the end of the manufacturing process, including cost-effectiveness, consistency, speed, versatility and ensuring food safety compliance. The bottom line: automating processes contributes to fewer line stops and shorter downtimes when they do occur (or are scheduled). Moreover, it helps ensure that people with the skills to handle required, planned operations are immediately available, since these are known in advance.

The task and the solution

Packaging is more than bags filled per minute and per day: “To find the best automated setup, understanding where the customer’s output is today and where they want to go in the future is key,” explains Blair Chastain, Chief Revenue Officer, Kwik Lok. “Our staff will work with customers to understand their current needs and make a plan for the future which includes a cost-effective and scalable approach to equipment and automation integration,” he adds.

Targeted solutions for semi-automated or high-volume, completely autonomous operations are available, each being mindful of footprint limitations and surrounding machinery. A bakery targeting expansion can start with semi-automated packaging systems, which can be later upgraded to higher volumes and additional features, Chastain illustrates. In this scenario, the space the system occupies requires (today and in the future) careful consideration, and is optimized by Kwik Lok engineers.

Packaging and coding

Changing operation needs is one aspect that determines packaging setups. The contents of the message on the packaging are another, as they complete the identity of the product itself. As needs and preferences for the information displayed on bags evolve, adjustments to the overall packaging process follow. Traditionally used Universal Product Codes (UPC) come pre-printed on the bags before packaging, to which the batch code is added. This is where variables can impact the results of the printing process on the bag: the shape of the product itself, the environment in bakeries and variations in temperature or humidity, for example.

Kwik Lok has created a new solution to bypass these challenges: closure labels including data resources such as 2D bar codes, which can now be printed in-line as a step in the packaging process, for large-volume production setups, and with semi-automated systems for mid-sized/smaller operations. Taking pre-printed bags out of the equation is more const-efficient, ensuring there are no leftover items with outdated messages.

The codes not only ensure the necessary information regarding the product is always available, but also provide new communication opportunities, in a simple yet effective way. Chastain explains: “We like to always emphasize to our customers how important it is to print on a flat surface. In cases where it isn’t possible, that’s where Kwik Lok comes in. With our closure labels and our closures, we have an opportunity to print directly on a flat surface, to consistently deliver the necessary information onto the product.” Whether on the closure itself or on a closure label, a code that can lead to a generous amount of data can be easily added to the product.

Through these codes, the product’s complete history can be included in the information delivered to the consumer, down to tracking all the ingredients going into it, for complete traceability. In this way, transparency requirements for the manufacturer can be met, as well as people’s need to learn about the product. For packaged goods that need to include the EU’s Digital Product Passport – a new initiative meant to advance sustainability and transparency, this solution is in the right place, at the right time. Implementing the code application is straightforward, with instant benefits. Kwik Lok can print that 2D barcode in-line to narrow down lot-level traceability to the item level – invaluable in mitigating product recalls, and damage to the brand’s image, for instance.

how important it is to print on a flat surface. In cases where it isn’t possible, that’s where Kwik Lok comes in. With our closure labels and our closures, we have an opportunity to print directly on a flat surface, to consistently deliver the necessary information onto the product.“

Blair Chastain, Chief Revenue Officer, Kwik Lok

Label enters production

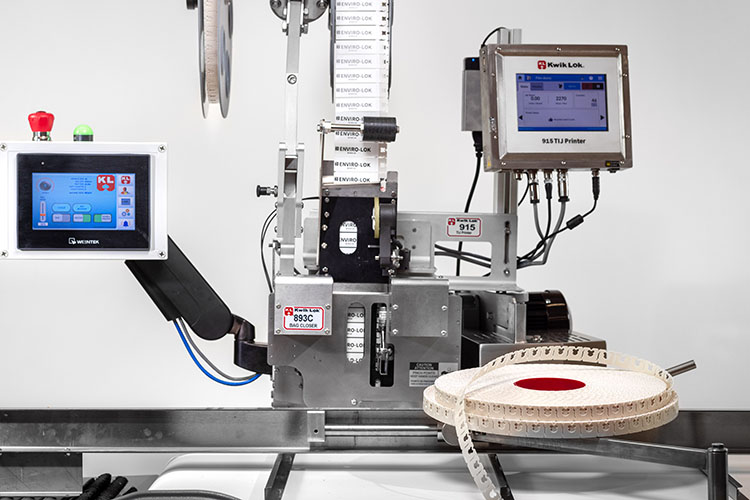

Fully automated packaging options mean that, instead of five people assigned to carry out manual operations, only one or two are needed, freeing up valuable hands for other operations upstream. The ‘all-inclusive’ systems provide, via a PLC, options for efficient packaging steps and predictive maintenance insights. The company’s automated equipment is label-ready, applying closures and labels on a single machine. Older models that might not offer this features can be upgraded to include it. A printer can also be added to the system, next to the closing machine, if one wasn’t in place already.

For the label, “We currently have a polypropylene-based option that uses less water, less CO2, and a lot less plastic – for the closure and the label,” Kwik Lok’s specialist highlights. The label itself can also be ultrasonically added, meaning no adhesives are involved, making it great for recycling where allowed. For a complete communication message, the label can contain information about how to best recycle it and the closure, too, with targeted instructions to match the requirements and infrastructure in each country.

The integrity of the labels is ensured throughout their journey, from the factory to the shelf, from the store to the fridge, and until the product is consumed. Billions of them are manufactured by Kwik Lok every year and are delivered on reels, ready to be applied with the machines.

The ink used to print the codes is also carefully considered: “Our printer uses a thermal inkjet currently, to make sure that it works well in environments typically found in bakeries,” says Chastain. “As a part of our R&D process, we are looking into more sustainable inks we can offer,” he adds, which can align with sustainability initiatives while remaining cost-effective. These goals are shared by all Kwik Lok developments, from machines to tracing and tracking tools, and material science advances.

A code that’s worth a thousand words

The closure’s mission starts by protecting the product’s integrity and includes compliance data; a new opportunity is now added, by including brand messages and transforming it into a communication tool via the 2D code. It has “the ability to speak to the consumer in the store, on the way home and it can continue to engage with them every time the product is opened and closed. This is very unique to our label,” Chastain underlines, adding in this way a new dimension to product branding. Labels are a compelling vehicle for consumers to engage with brands, putting a digital spin on a traditional marketing concept, which ultimately elevates sales, Kwik Lok observes.

The closure-and-code pair is starting to be adopted across industries, and food items can certainly benefit, too, from ability to connect with the consumer digitally more than via the well-traveled roads of communication that are usually taken. It is the perfect solution to the Digital Product Passport requirements in Europe, for example. The information, which can include nutritional information, ingredient sources and special offers or promotion announcements, is not intrusively offered and the call to action is welcomed, since it’s a piece of information that has been actively requested by accessing the code. Kwik Lok notes that engagement rates can be 10 times higher than any other channel, which is a powerful tool for a very cost-effective label. And, as with all digital information, the content shared can easily be updated. Moreover, its performance can be tracked – for real-time monitoring of the effectiveness of the message. When campaign changes are made, visible results are available to assess their impact, since analytics reports of the data usage are generated.

The EU Digital Product Passport

Starting in 2024, the European Union implemented a new regulation requiring nearly all products sold in the EU to feature a Digital Product Passport (DPP), to advance transparency and sustainability. This initiative is part of the Ecodesign for Sustainable Products Regulation and aims to provide comprehensive information about each product’s origin, materials, environmental impact and disposal recommendations. The DPP is designed to close the gap between consumer demands for transparency and the current lack of reliable product data.

The DPP will include essential details such as a unique product identifier, compliance documentation, and information on substances of concern. It will also provide user manuals, safety instructions and guidance on product disposal, according to the announcement made in September. “By offering a detailed digital record of a product’s lifecycle, the DPP will enhance supply chain management, ensure regulatory compliance, and help companies identify and mitigate risks related to authenticity and environmental impact,” it said.

By making detailed product information publicly available, the DPP supports open data initiatives that emphasize transparency and accessibility. The EU anticipates this approach will improve product visibility and sustainability practices. At the same time, it will facilitate better data sharing and collaboration across the industry.

The EU moves toward full adoption of this new regulation, to enhance both the visibility and integrity of product information via the DPP, benefiting companies, consumers and the environment.

Complete solutions

In its work to provide the most suitable solution, the American-based company partners with different suppliers that can offer platforms for digital data management, as well as their seamless integration. The interface is easy to implement, utilize and maintain, when building and updating data to be shared. “We have dedicated engineering staff to make sure that all the different bakeries worldwide receive the solution matching their bagging preferences, taking into consideration the specifications of the bag manufacturers of their choice for consistent packaging results,” Chastain explains how packaging equipment is engineered, with corresponding coding features, for the desired materials.

Kwik Lok is also working with partners to ensure data management and safety, with no exceptions. Additional ideas on how to creatively use this kind of data are also developed through these partnerships, for a new spark of excitement in communication with the consumer.

To be continued

“Using a label as a marketing piece might be still in its infancy, but that is the future, and the amount of interest that we have in there already proves that,” Chastain summarizes the exciting new opportunity. As always, upgrades are built on perfect compatibility between all

elements involved, packaging machine, label material and production flow.

It allows brands to experiment with what can have the highest impact, in their messages. Achieving this level of transparency in communication builds trust; with it, comes the willingness to pay attention to the product’s messages. “We know how powerful a pretty simple interface can be, with just a coupon, a promotion or a sweepstake,” Chastain underlines. The window for creativity (and earnings) is wide-open, now with a digital interface for content management. And the time is now, as post-pandemic consumers have acquired the habit of scanning codes and researching items, starting with food products, for how they impact their health and safety, their sustainability positioning, and to verify that the brands they associate with validate their values.