PART I

Soft dough biscuits are among the popular snacking choices worldwide. Their success comes, in no small part, from their diversity, combining flavor offerings and playful shapes. Recipes may call for inclusions or enrobing, to further expand the variety of this exciting product segment. Flexibility is a must for the corresponding technology to support this level of creativity.

Inviting with their diverse iterations, biscuits are, nevertheless, a delicate business to master. Following careful preparation, the fragile products are thoroughly inspected so that they may begin their journey to the consumer in great condition, and remain that way until snack time. The competition for attention matches their diversity, which is, at the same time, their unique selling point.

Process-by-process optimization

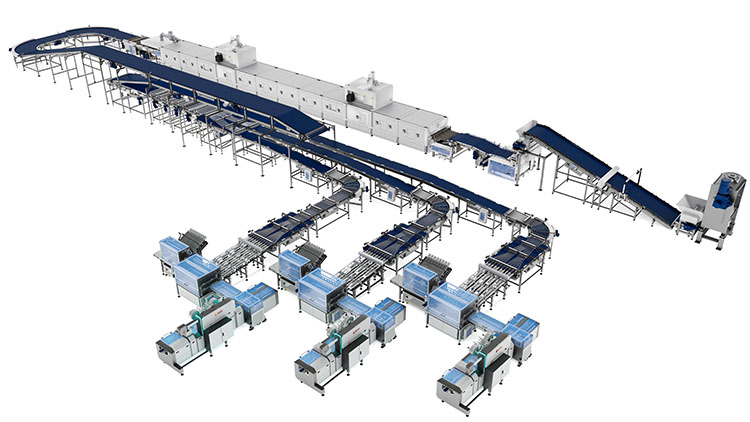

New Era Machines designs and develops turnkey industrial production lines for molded soft biscuits. This line was developed with the purpose of maximizing production versatility, the specialists of the Indian company highlight: “Through extensive research and innovation, we engineered the line to accommodate a wide range of dough consistencies and formulations, allowing for the production of various biscuit types.” The line’s flexibility is achieved by incorporating adjustable parameters and versatile machinery components, they explain, to accommodate an extensive array of biscuit products and achieve the desired end-product quality.

The line comes with a modular feeding system, specially designed for biscuit production. It offers several benefits, starting with streamlining the dough feeding process. This is done by automating the distribution of dough to the forming system, which reduces manual labor while also ensuring consistent dough quality and accurate portioning, resulting in enhancing product uniformity. Additionally, the modular design means that the line can be easily customized and scaled, facilitating seamless integration into existing production setups and accommodating future expansion needs.

The design of this line’s forming system also takes into consideration diversity in product demands. “We learned from the operators and customers running our machines for decades and have employed all the features necessary for quick changeovers of the molding roll and the endless belt, as well as variable speed settings to meet the process requirements and a wide range of baking times,” according to the specialists from New Era Machines. Customizations are also possible; for example, the machine can be built so that it is suitable for wash-down cleaning.

The New Era lines for soft biscuit production can also integrate equipment with various techniques of applying inclusions. They are equipped with precision dosing systems and deposition mechanisms to accurately deposit inclusions such as salt, sugar, sesame, or nuts on the surface of the dough. Next is the oven – arguably one of the most scrutinized pieces of equipment on a line. For the production of soft biscuits, convection technology is widely the oven of choice, for its baking efficiency. As care for resources spent has become a ubiquitous concern, New Era observes that hybrid ovens have become the most popular request. The company meets this demand with its oven technology, which is designed to optimize energy consumption and product quality: “By combining direct heating and convection, our hybrid ovens provide precise temperature control and rapid heat transfer, ensuring consistent baking results with minimal energy usage. Additionally, advanced insulation and airflow management features further enhance efficiency, reducing heat loss and maximizing oven productivity,” the specialists describe.

“By combining direct heating and convection, our hybrid ovens provide precise temperature control and rapid heat transfer, ensuring consistent baking results with minimal energy usage.”

New Era Machines specialists

Hygiene and product safety are also high on the priority list, with a decisive uptick over the past few years, which is reflected in equipment R&D. The latest developments in line design at New Era Machines prioritize hygienic design principles and product safety standards: key features include smooth, easy-to-clean surfaces, sanitary construction materials. “Our machines are also equipped with advanced safety features such as interlocking guards, emergency stop buttons, and comprehensive safety protocols to protect operators and ensure compliance with industry regulations. Based on the installation country, CE, UL or CSA can be certified,” the specialist highlights.

Optional features that can be added to New Era biscuit production lines include customized decorating systems, automated packaging solutions and custom solutions for specific requirements.

The lines can be designed to evolve together with the manufacturer and keep up with later plans for additional product ranges. For instance, if a manufacturer is installing a soft biscuit line today but wants to keep their options open and also be able to produce hard biscuits in the future, several features can be considered from the initial design stage, including necessary space for future expansions, oven technology suitable for both hard and soft biscuits, the technology specialists illustrate.

Things are under control

Process controls play a crucial role in ensuring consistent product quality and operational efficiency. New Era Machines biscuit production lines are equipped with control systems that monitor key parameters such as temperature, speed, and power throughout the production process. These controls enable operators to make real-time adjustments, optimizing production parameters and minimizing waste. Additionally, comprehensive data logging and analysis capabilities allow for continuous process improvement and quality assurance.

To achieve a balance between product diversity and optimum process efficiency, careful planning is required. “To maximize efficiency without sacrificing product variety, manufacturers should focus on streamlining production processes, optimizing equipment utilization, and investing in flexible machinery solutions,” New Era says, recommending the implementation of modular production systems, standardized workflows, and advanced automation technologies, to ensure production adaptability. Additionally, continuous monitoring and improvement of key performance metrics can help identify areas for optimization, they note.

The newest developments in biscuit production machinery at New Era focus on enhancing performance, flexibility, and sustainability. Key advancements include improved automation capabilities, enhanced energy efficiency features, and fine-tuning technology for product innovation and differentiation.