Part II

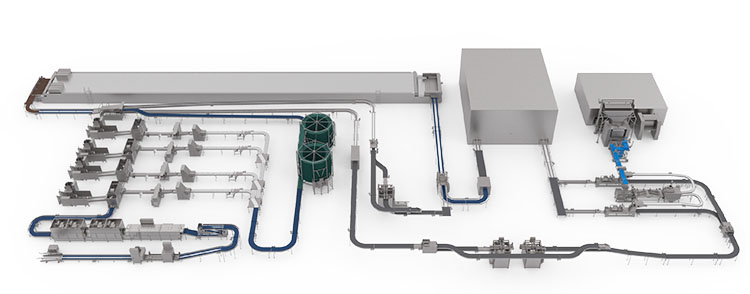

Complete solutions are an attractive proposal for bakeries. It is particularly relevant when considering the hassle of compatibility issues and process inconsistencies between parts being transferred to the experts, together with a wish list of what a production line should be able to do.

There are numerous challenges in integrating solutions for a turnkey project, starting with ensuring compatibility between various pieces of equipment. These include meeting specific production needs and maintaining high standards of quality and efficiency throughout the process.

THOROUGH PLANNING: AMF BAKERY SYSTEMS

Coordinating multiple suppliers with components coming from different manufacturing locations, managing timelines, and ensuring that all components work seamlessly together can be added to the list of significant challenges in a turnkey project. “It requires meticulous planning and collaboration across all stakeholders to ensure that the project remains on schedule and meets all specifications,” underlines Andrey Bulatov, Sales Support Engineer, AMF Bakery Systems.

Compatibility problems can arise in several areas, such as working with differing software protocols between machines, mechanical mismatches (e.g., when using imperial vs. metric systems), and varying electrical requirements. AMF suggests addressing such issues by:

+ Standardizing interfaces, ensuring that all equipment integrated into the line uses standardized communication protocols;

+ Custom engineering, modifying equipment to meet specific requirements;

+ Comprehensive testing – conducting thorough pre-installation testing to identify and resolve issues early.