Continuous baking: Go with the flow!

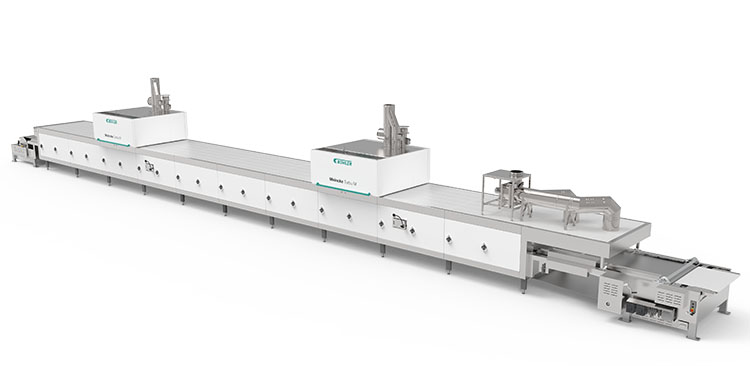

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

Bühler sees an increase in requests for flexibility regarding energy sources, energy-saving solutions and alternative heating technologies. To these, sustainability commitments are added, which also translates into an increasing interest in carbon-neutral solutions.

Bühler announced the delivery of its first Prime Masa plant in India – the second Prime Masa plant worldwide – to PV Sons Corn Milling. The plant will consume 84% less water, 52% less energy compared to a traditional process.

Flexibility is the top priority when manufacturing cupcakes and muffins as well, as highlighted by the Unifiller Europe Flexline, one of the favorites among the Linxis Group specialist’s customers. This line can first be used for depositing muffin and cupcake batters, and (after baking) for the injection of fillings or cupcake decorations.

Small baked goods production: Innovative dough dividing, forming and depositing in a single step with the FS 520 forming system.

For the production of small pastries, the plant manufacturer Handtmann offers solutions for fully automatic production.

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/Riss, offers various solutions for the industrial production of toast-bread.

There are both automatic and manual solutions for cookie production.

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/Riss, offers various processes.

JAC, a manufacturer of bread cutting/slicing machines and dough processing plants, invested several million Euro in a new production facility in Lüttich, Belgium, in 2019.