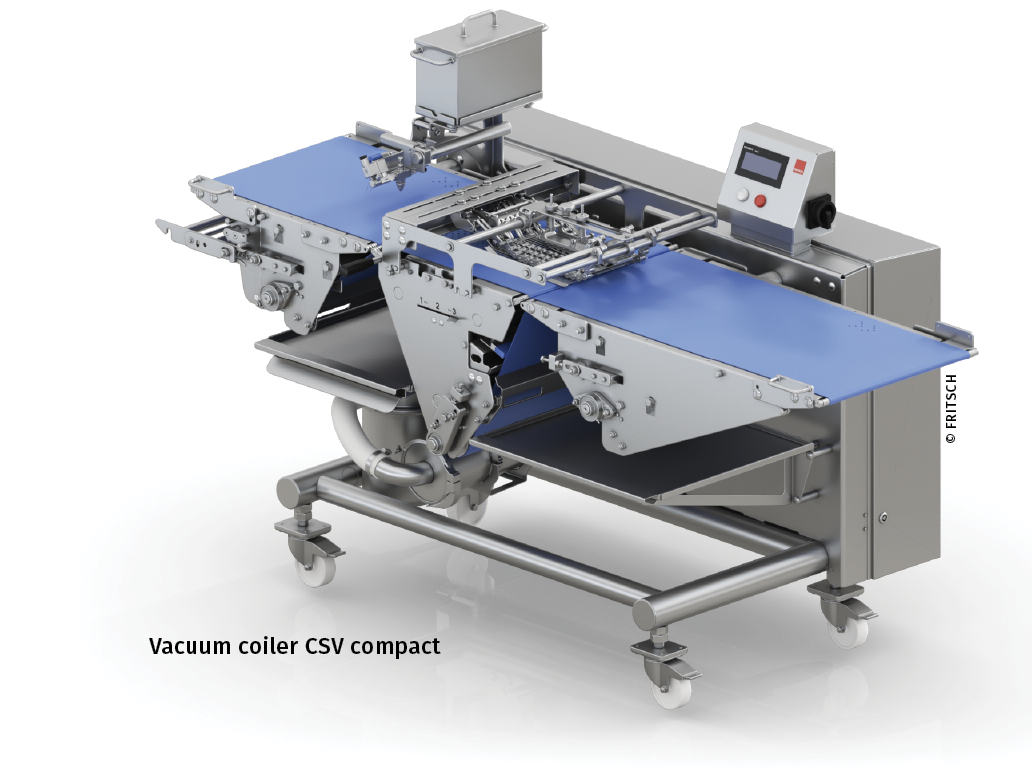

Vacuum coiler with additional benefits

The FRITSCH CSV compact is a vacuum coiler that fixes the dough pieces or the dough pieces cut into triangles on the belt by means of a vacuum, which prevents them from slipping whilst coiling.

The FRITSCH CSV compact is a vacuum coiler that fixes the dough pieces or the dough pieces cut into triangles on the belt by means of a vacuum, which prevents them from slipping whilst coiling.

The semi-automated production of Polsehorn on a large scale – that was the task with which a Danish company approached the bakery machine manufacturer FRITSCH.

Manufacturing donuts with less fat and sugar is a must. However, this is just the starting point as unusual shapes, new flavor experiences, creative textures and hybrid formulations are on the rise.

Depending on the size and desired capacity of the operation, there are several systems that best support the environment and production needs.

The bakery plant manufacturer FRITSCH has redesigned the LAMINATOR 300. The sheeting line is even more flexible and gentle in dough treatment.

Small baked goods production: Innovative dough dividing, forming and depositing in a single step with the FS 520 forming system.

For the production of small pastries, the plant manufacturer Handtmann offers solutions for fully automatic production.

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/Riss, offers various solutions for the industrial production of toast-bread.

There are both automatic and manual solutions for cookie production.

Albert Handtmann Maschinenfabrik GmbH & Co. KG, Biberach/Riss, offers various processes.

Fritsch’s Product Decoration Unit (PDU) allows the gentle, precise molding of patterns on a variety of dough pieces, and does so regardless of their shape and weight.