Continuous baking: Go with the flow!

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

The automated line designed by AMF Tromp can flexibly support a wide range of pies, either savory or sweet, in a baking tray, in foils, or in paper cups. They can bake the pie shells only, pies with the top opened or closed and pies with or without a lattice decoration. For (pre-)baking the pies, AMF recommends a Den Boer Multibake tunnel oven with impingement heating or a direct-fired system.

For industrial production, pizza lines are made to welcome any variations required. Accurate processes are a must for these flexible lines.

Royal Smilde is known for its rich diversity of sweet and savory baked creations. Either sold under its own labels, through collaborations, or as private labels, the products made by the Dutch bakery are in growing demand worldwide. A very flexible production line helped them increase production volumes, built by AMF Bakery Systems (Tromp). Particular care was given to automating apple turnover production, namely – dough folding into a triangle.

While recipe variations for baguettes and bread rolls are not only to be expected but also make for unique selling points, high hydration rates and long dough resting times are the calling card of more sophisticated, authentic premium products.

The Dutch ‘silo to truck’ solutions manufacturer develops production lines for all kinds of freestanding bread, with a capacity of around 7,500 kg/h, depending on the production process, type of end products and available space.

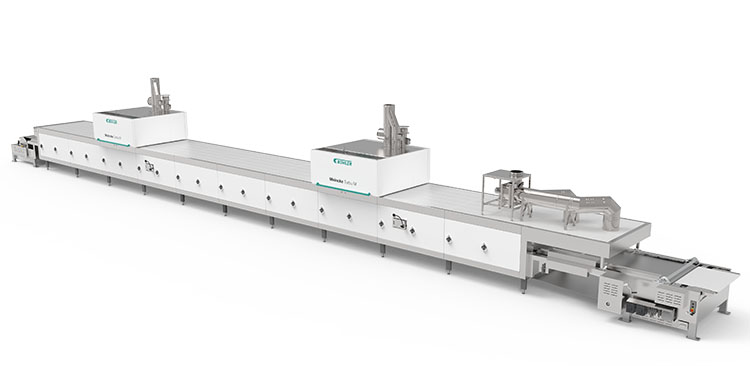

MECATHERM will introduce its latest advances to tackle the sustainability and digitalization challenges in the manufacturing of baking and sweet goods. The French specialist will showcase its complete solutions at the show, focusing on solutions to optimize energy efficiency, a new, easy-to-clean oven dedicated to delicate products, and its latest digital solutions.

Sweet or savory, pies are a perennial favorite among consumers. Highly specialized production lines are developed to ensure production meets quantity as well as quality needs, efficiently.

This year, the French specialist focuses on solutions for energy efficiency, the new, easy-to-clean M-DAN oven and new digital solutions for industrial performance. MECATHERM is launching the new M-DAN Oven, with an improved hygienic design that includes wash-down capability.

Scoring is a process that requires skill and shows the baker’s experience when done manually. Alternatively, as labor is becoming harder to find (and then keep), robots can efficiently take over the task; they will never need to stop and will perform constantly over time.

Mecatherm, French manufacturer of industrial ovens and production lines, has signed a partnership with American ABI Ltd, a specialist in bagel makeup equipment. Together they are planning to market an industrial bagel line. baking+biscuit international investigates further.

Mecatherm, French manufacturer of industrial ovens and production lines, has signed a partnership with American ABI Ltd, a specialist in bagel makeup equipment.