Continuous baking: Go with the flow!

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

Artificial intelligence (AI) in manufacturing is no longer a fascinating idea – it is already here and accelerating quickly throughout many industries, especially in the baking industry. Several reasons are fueling this revolution.

Product waste in industrial bakeries can arise from several factors, each contributing to the overall inefficiency of the production process. Understanding these causes is crucial for developing strategies to mitigate waste.

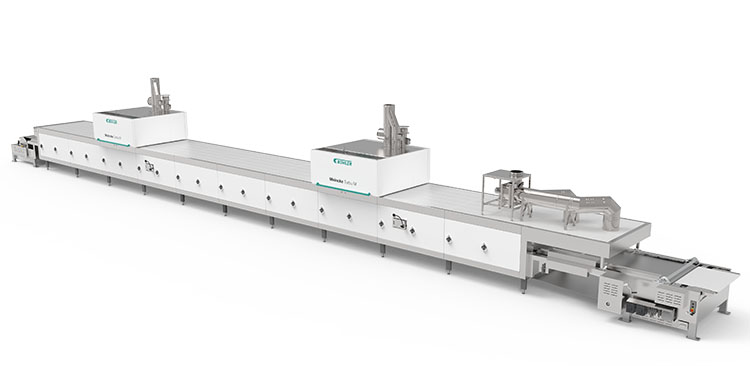

The automated line designed by AMF Tromp can flexibly support a wide range of pies, either savory or sweet, in a baking tray, in foils, or in paper cups. They can bake the pie shells only, pies with the top opened or closed and pies with or without a lattice decoration. For (pre-)baking the pies, AMF recommends a Den Boer Multibake tunnel oven with impingement heating or a direct-fired system.

Automated inspection systems are able to guarantee top product quality and safety – no exceptions allowed. In-line vision inspection technologies comprehensively inspect 100% of the products throughout the entire manufacturing process.

For industrial production, pizza lines are made to welcome any variations required. Accurate processes are a must for these flexible lines.

A new AI image-recognition service is unveiled at iba, which tracks in-store patisserie and bakery shelf performances in real-time. AI specialist MarketLab, in partnership with Puratos, developed Spotimize to help with shelf management, lower waste and improve the customer’s experience. During its current startup phase, the Spotimize service will be available to a limited number of customers in selected countries.

ECD will bring its thermal profiling technology to iba in October. The handheld M.O.L.E.™ EV6 sets a new benchmark for thermal data loggers, delivering instantaneous data access and intuitive control – now with a full-color touchscreen display. In addition to the six-channel M.O.L.E. EV6, the company’s BreadOMETER™, CakeOMETER™, and OvenBALANCER™ sensors will be demonstrated at the stand.

KPM Analytics showcases solutions that meet growing trends such as automated product inspection, process control achieved with vision inspection, processing whole wheat/high-fiber products, at-line dough quality analysis, and ingredient quality control.

‘Artisan’ and ‘premium’ are often used interchangeably when referring to bread. To Koenig, ‘premium’ products are crusty breads, with complex flavor and a chewy crumb.

The Dutch ‘silo to truck’ solutions manufacturer develops production lines for all kinds of freestanding bread, with a capacity of around 7,500 kg/h, depending on the production process, type of end products and available space.

ECD’s M.O.L.E.™ EV6 touchscreen thermal profiler is now commercially available, with shipments starting April 1. The interface is said to have a user-friendly, intuitive design engineered to save baking professionals time, simplify data viewing and analysis, and improve productivity.