The key to continuous baking success is in the oven. For biscuits, crackers and cakes, a steady, continuous production flow is ideal in high-volume operations.

When looking for continuous baking improvements, tunnel ovens are the undisputed choice in terms of flexibility and efficiency. New developments incorporate new concepts to save energy, improve hygiene and support product diversity while being easy to operate.

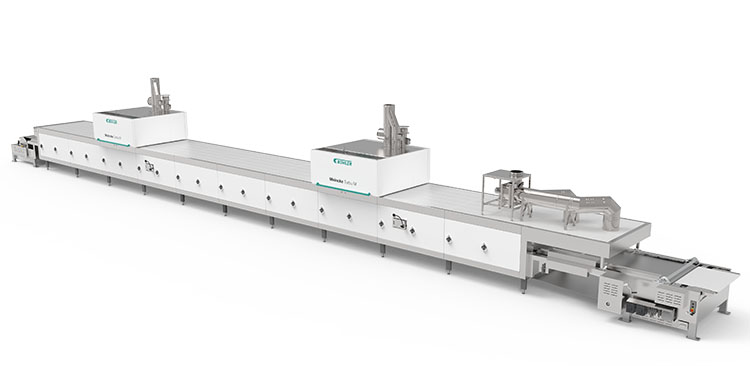

Bühler recently launched the Meincke Turbu M – a mixed-energy solution: “Meincke Turbu M is an indirect forced-convection (IFC) oven that features both a gas burner and a rack of electrical heaters. It ensures precise temperature control and uniform heat distribution, leading to consistent baking results,” Bühler explains. Both energy sources can be used to support the baking process simultaneously. The oven can shift from gas to electricity (or use them simultaneously), depending on the more convenient source to use, without having to stop the production process. “Bakers can fine-tune temperature settings and baking times for optimal results, regardless of the energy source. The oven‘s control systems support precise adjustments to maintain consistent quality,” the specialists detail.

The Meincke Turbu M achieves energy savings of up to 8 % in full electric mode compared to gas mode, while also decreasing CO2 emissions significantly. Bühler recommends “Using the most cost-effective energy source, leveraging dual-energy adaptability, and maintaining the oven regularly to ensure peak efficiency.”

The oven uses Bühler’s newest heat transfer technology features to ensure even baking for a wide range of doughs and recipes, with adjustable baking zones so that temperature and humidity can precisely be adjusted in different sections as needed. This continuous baking oven was designed specifically for the large-scale production of high-quality goods – biscuits, crackers and cakes – of various textures, sizes and flavors.

The new technology comes with several automation features, including user-friendly controls, remote monitoring, and connectivity with Bühler Insights for performance tracking. It has an intuitive interface that supports process monitoring and parameter adjustments. “Updates include enhanced connectivity, and Bühler Insights provides tools for data-driven baking management,” the specialists outline. Regular updates should be expected, as a part of Bühler’s focus on innovation R&D.

Heating principle of the Meincke Turbu M oven:

+ A fan blows air into the burner chamber, which is heated directly by the burner.

+ The accruing heat is transferred to the heat exchanger room.

+ There, air is heated up in a separate system and distributed to the baking chamber. This ensures that no combustion gases come into contact with the end product. A constant, correct baking temperature is achieved, which secures uniform baking results.

The Meincke Turbu M supports various baking capacities, depending on the type of product. “Production lines with widely varying energy demands and product ranges benefit the most from using this oven,” the specialists of the Swiss company highlight. Baking cycles are also customized to the product category, each with precise temperature control and duration, as well as optimum energy consumption, with minimum heat losses.

When changing from the gas-fired Meincke Turbu 4.0 to a Meincke Turbu M, there is no need to adapt existing recipes from previous production programs. The dual energy kit can also be retrofitted onto existing Meincke Turbu 3.0 or 4.0 gas oven models. It is installed by replacing the heat exchanger, adding electrical heaters and updating the control system. The process typically takes two-three days per section, for mechanical work and software updates. For an oven to be eligible to incorporate the new technology, “Proper infrastructure support is required to accommodate the dual-energy module,” Bühler notes.

n line, including recipe programming, and data analysis,” explains Melanie Gay, Marketing Manager, VMI.

SPI mixers offer customizable settings for various parameters, including the number of phases, mixing time, mixing speed, duration of each phase, bowl rotation direction, and temperature control. When saving a new recipe, you can also preset how the ingredients will be added. They can be brought out of the mixer through the hatch on the cover or by raising the mixer’s head. The level of automation can be chosen as needed: “Manual mode can be used for some productions, while pre-created recipes can be used for others. Operators can easily select and launch recipes, and receive visual or sound alerts for actions, such as cycle completion or ingredient addition,” she explains. For pre-configured recipes, while on automatic mode, the operator simply selects the recipe and starts the process.

Bake for less

Bühler’s latest developments are in line with a growing request for electric ovens, focusing on using more sustainable energy sources instead of fossil fuels.

The Meincke Turbu 4.0 gas oven and the Meincke Hybrid (with DGF and IFC zones) can be tested at Bühler’s Innovation Center in Denmark with products already developed, or to perfect new recipes. Energy-efficient configurations can be explored for the optimum settings of each product. “This allows experimentation to determine optimal energy use and baking parameters tailored to specific needs,” the specialist says.

For new product development in the biscuit and cracker categories, Bühler suggests developing recipes to leverage the Turbu oven’s consistent temperature control and even heat distribution. Among the priorities should be the selection of ingredients and fat content for the right balance of flavor, texture, and stability during baking, the specialists recommend.