An enticing range of breads is carefully crafted to answer the consumer’s unwavering love for a slice of wholesomeness, whether it’s an artisan-style bread or roll, ciabatta, focaccia, or a baguette. It’s their time to shine, in all creative interpretations, with the technology ready to reliably back up production.

A relaxed dough makes the best bread! For artisan breads of European inspiration (and beyond), dough need not only to be stress-free during the process, but also well-hydrated, in many cases.

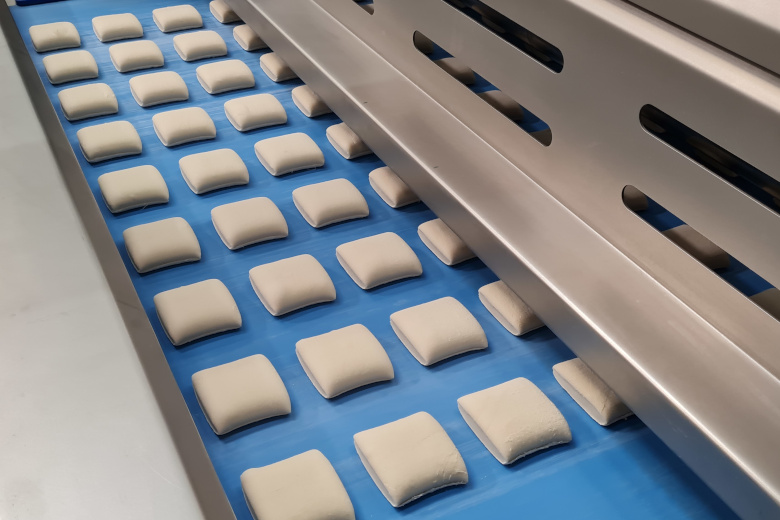

Flexible, high-speed lines

The stress-free sheeting technology developed by AMF Tromp is at the heart of the processing line for any artisan bread product. The technology was developed around maintaining the quality and integrity of the traditional craft, according to the company. Several features have been built to meet specific manufacturing demands, including the possibility for oil-free sheeting, and dedicated make-up options for cut, rounded and molded products. The in-line molding section de-gasses dough for better and finer structures in the final product. Adjustable mesh belt takes care of the first curling of the dough piece, and the motor-driven molder board does the final step to deliver the product in a pan, or on a peel board. With this system, the dough is not only stress-free but also sheeted at high speeds. Its design has eliminated falling heights so that thickness reduction is carried out without bringing any tension to the dough band. “Incorrect reduction factors, including inadequate speeds, can bring too much tension and stretch the dough sheet unnecessarily, damaging its structure and even causing it to tear,” AMF Bakery Systems points out.

When volumes are of the essence, the SFA line is designed to handle large-scale operations: “Our solutions reach up to 4,000 kg dough per hour, so industrial capacities for high volume lines can be guaranteed,” AMF details. Half of this or even smaller volumes can also be prepared efficiently, with no resource waste, thanks to the built-in flexibility of the line as well as its modular design. Smaller operations, as well as changes in volumes required, can be accommodated in this way. Adding to its flexibility features, the AMF Tromp line features top and bottom flour applicators and customizable seeding options that bring diverse seed varieties to certain sides of a bread. Decorative scoring with water jets can add even more variety to the product lineup. Special care is taken of baguettes: a pointer can help shape “true artisanal baguettes” with pointed ends, AMF underlines. Its flexibility does not come at the expense of process efficiency, either.

Sanitation is also factored into the machine design: the AMF Tromp Breadline can be washed down. Automation is also ensured so that a team of one or two can manage the process. They set up the line, select the recipe, and then only need to supervise the production, as almost every step of manufacturing artisan-style breads with AMF equipment can be automated.

The AMF Tromp line can be upgraded to support new product ranges. A system that makes cut products, for example, can easily add molded or rounded varieties, using the same sheeting line. Robotics can also be brought to the line anytime, for a step up in automation. Integration with AMF mixing, proofing, baking and cooling systems, can be made seamlessly, using the same software and process controls by AMF.

Photos: AMF Bakery Systems

The article is part of an in-depth feature published in Baking+Biscuit International, issue 1 – 2024.