INTERVIEW

Juri Winkler was recently appointed Sales and Marketing Director of DIOSNA, a LINXIS Group company. He shared with us his views on the current and future direction of the company, the ‘dough experts’, based in Germany, and its latest developments, including a new IoT solution.

PRODUCTION

One characteristic shared by different types of bakeware, from trays to pans or cake molds is their mission to make the baker’s life easier.

To manufacture rolls and buns with consistent quality for the lowest possible costs, efficient systems are a must, to produce the required volumes and varieties and provide solutions to any number of production challenges.

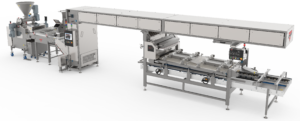

With flatbreads growing more and more popular, dedicated production lines focus on delivering premium quality results. When developing its flatbread line, König focused on replicating artisan-like characteristics.

Several methods can be used for depanning baked products safely. Automation provides the next-level tools for maximum flexibility and reliability. The good news is that it does not require replacing a whole line to incorporate.

FREEZING AND COOLING

Formulating and perfecting the recipe is only the start to having great-tasting, crunchy or soft bakery products. The freezing process is essential to how their properties will be captured and preserved.

CONVEYING

Reliable product transfer between processes is essential to maintaining the rhythm in production sequences, with continuous, automated adjustements. To optimize efficiency in industrial baking, everything is riding on conveyor systems.

Energy consumption tops the list of concerns for bakeries. The first place to start looking into potential savings is, of course, the big spender – the oven. Here, steel belts can go a long and hygienic way toward baking efficiency. Keeping them in a straight line is key.

PACKAGING

Syntegon has developed a new solution for the handling and portioning of cookies and crackers. The compact, smart machine ensures gentle processing as well as flexibility.

SCIENCE

Resource scarcity is affecting nearly all sectors of the economy worldwide, with the baking industry being no exception. The massively increased energy prices are currently the main concern for bakeries, but recurring shortages of raw materials and personnel are making the situation worse. This article aims at describing the current issues of resource scarcity and proposes solutions – mainly in the technical field – to tackle the crisis.

One of the popular uses of vacuum cooling is for laminated pastry products. Campden BRI carried out a research project on vacuum cooling for bakery products to investigate the scientific issues that arise when cooling bakery products including laminated pastries, sandwich bread and cake.

SUSTAINABILITY

The name is well chosen. ‘Heldenbrot’ (Hero Bread) is the label under which the start-up Kultimativ gives leftover bread a second chance by processing it into cookies or other products. And the consumer also feels good from being a ‘food savior’.