Stress-free dough processing guarantees artisan-like product results for all kinds of breads and rolls and for any production volumes. Gentle dough reduction is key.

Consumers’ changing perceptions of the nutritional value of foodstuffs, combined with a renewed interest in bread, have made the segment of artisan breads become particularly interesting. Clean labels are valued, and so are traditional types of products, not only for bringing up nostalgic taste experiences, but also because of the connection with simplicity and healthy eating. For breads and buns, this means baking doughs with a high water percentage, which requires gentle handling and especially stress-free reduction. Sheeting is the best process that ensures their high-volume production.

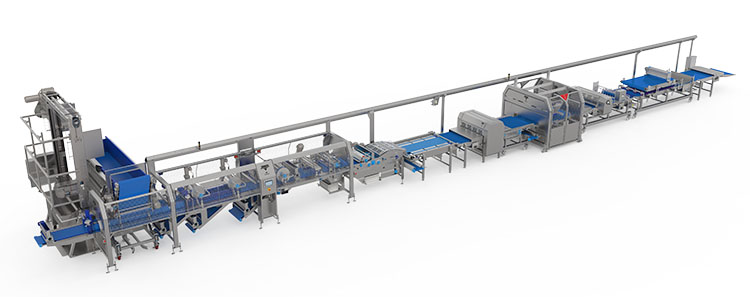

NEW: AMF Tromp artisan sheeted bread line

Gently reducing the dough band ensures the air bubbles stay put and the resulting bread products will look, taste and feel handmade. Working with living organisms as ingredients requires mastering the technique and the art of the craft, and technology can reliably replicate the master baker’s care. AMF Bakery Systems has been perfecting sheeting technology for decades to deliver complete process control as the dough is transformed from a bulk mass into a continuous sheet of dough. Relaxed dough throughout the process is key.

The company now offers new technology to support the production of artisan-style creations: the AMF Tromp artisan sheeted bread line, which will make its official debut in the world of baking at iba 2023. The new line features major upgrades designed to simplify its operation and maintenance, and enable greater process control. “We measure the process, dough quality, speed, dough width, volume, flour application, centering of the dough sheet, amount of waste/trim, and more,” AMF lists some of the features that help control production. At the same time, the line brings energy-use optimizations and also requires less water, both in-demand features for must-have sustainability technology improvements.

The new equipment has even taken out any falling heights to protect the dough’s integrity. In this way, the dough will not stretch and alter its structure, so the fermentation results will stay within the intended parameters. The dough is also kept in control by applying flour on the top, bottom and sides. AMF Tromp’s patented flour applicator carries out this task – its unique characteristic is the ability to bring flour onto the sides of the dough sheet, improving a stress-free flow. “More process control is what every industrial bakery wishes to achieve, delivering constant quality and throughput every minute of the day, every day of the week,” AMF underlines. With this system, there is no longer any need for oil on the production line, even when working with ‘sticky’ dough, which means easier cleaning, minimizing waste and saving the oil for other uses.

“More process control is what every industrial bakery wishes to achieve, delivering constant quality and throughput every minute of the day, every day of the week.”

Hans Besems, Executive Product Manager, AMF Tromp

Working smarter and faster

The new system covers all processes, from mixing to de-panning – at high speed and for high volumes. It has a capacity of up to 4,000 kg of dough per hour and can be used to produce a wide range of specialty products. The make-up stage plays a role in the production capacity of course, with proofing and baking times taken into account. Since it specializes in artisan-style goods, it is designed to handle high-moisture doughs with efficiency. A notable design improvement of the line is that it uses Artificial Intelligence (AI) to enhance product accuracy and minimize dough waste.

The upgraded line contributes to improved labor distribution, too. Its simplified modules have a ‘toolless sanitation’ design that do not require additional tooling for changeovers, cleaning, or maintenance operations. Changeovers can be done very fast, with minimum downtimes, so several types of products can be planned and brought into production in the course of one one day or shift. It also means there is easy access to all the parts that require maintenance, and cleaning can be easily carried out. The AMF Tromp system complies with the EHEDG hygienic design guidelines.

Extensive research went into the development of this line, to address current production requirements. Its modular build means it is flexible to adapt to changing requirements, too. It comes with a range of precision equipment, including an inline rounder that can produce boules of up to 1 kg and a top and bottom brush system that removes excess flour. There are several make-up and decoration features available: for example, top and bottom seeding, automated inline water splitting and precision molding for products of different shapes and sizes.

More sustainable production was another key design consideration. The system not only runs with less water (to run and for cleaning) and energy, but also helps reduce waste – for example, its dough-centering unit ensures minimal dough trimming, resulting in less waste.

New equipment

To shape products, AMF designed and engineered a new rounding solution, which will also be showcased at iba. Using feedback from bakers, the specialist built the rounder to make the process as artisanal as possible, as if the baker was rounding by hand. “From small dough balls to the large and 1 kg breads/boules, the rounding process makes them look unique, and still the same every time,” the specialists describe.

A newly designed guillotine also supports bread production. Aside from cutting, its traditional task, performed without misshaping the products, the traveling guillotine also seals products. Toolless changeovers are possible for this unit as well and it incorporates improved hygiene features. iba visitors will be the first to see it on display.

Technology lines for all types of bread

AMF Tromp breadlines deliver sheeting technology that is renowned in the baking industry. They support an unlimited product diversity and can accommodate growing trends, including gluten-free and vegan recipes. “The dough sheeting process is determined by the type of dough, but, after that, the variation is endless – all shapes, sizes and weights can be made, either rolled, cut, or molded, with any kind of fillings and decorations,” the company notes.

Supporting variety and automation in breadmaking is a core focus at AMF, with an extensive portfolio of solutions that help improve the process and the results ranging from belt or step proofers, to tray and peelboard handling equipment, and its Den Boer tunnel ovens. Sheeting lines for bread are custom-configured; they handle the dough gently, but with high speeds. To customize solutions addressing each particular baking facility, “Footprint in the building, capacity, production hours, level of automation, proofing times, baking times, and switches per day – these are all factors we take into account when designing new lines,” AMF explains.

Process efficiency is ensured by comprehensive control, establishing recipe-driven settings throughout the production lines, as well as increased automation with reduced need for operator intervention. Smart features go a long way to improving production efficiency, too. “Our systems get smarter using Machine Learning,” AMF highlights.