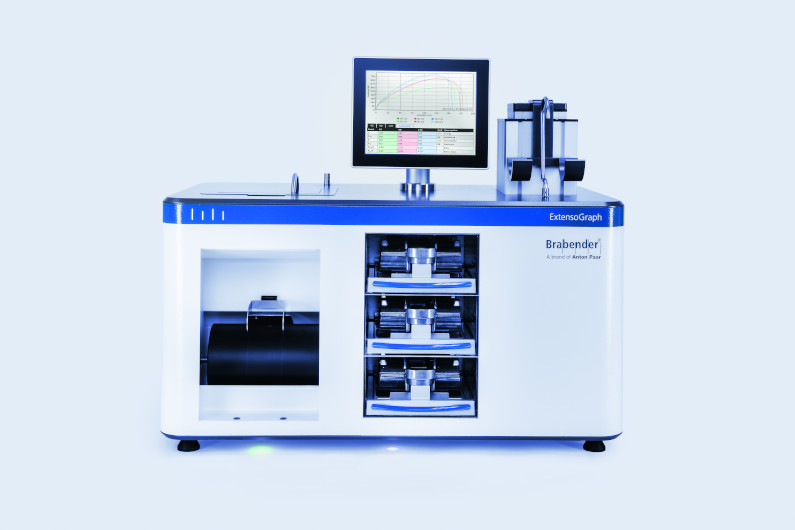

Anton Paar brings quality control solutions to iba ‘25

At iba 2025, Anton Paar exhibits at iba with the theme ‘Advanced Quality Control, focusing on solutions for quality control in the baking, food and ingredient industries.

At iba 2025, Anton Paar exhibits at iba with the theme ‘Advanced Quality Control, focusing on solutions for quality control in the baking, food and ingredient industries.

MULTIVAC Group acquired an 80% majority stake in Italianpack S.p.A., a manufacturer of automatic and semi-automatic packaging machines headquartered in Como, Italy. Italianpack will be incorporated into the MULTIVAC organization as a new business unit under the leadership of Tomaso Petrini, CEO of Italianpack.

With BVT’s turnkey line, product variety extends beyond sweet and savory pies, which by themselves make up for a diverse product range, to begin with. The fully automated Pieline can handle all types of pies, tarts and cakes.

The automated line designed by AMF Tromp can flexibly support a wide range of pies, either savory or sweet, in a baking tray, in foils, or in paper cups. They can bake the pie shells only, pies with the top opened or closed and pies with or without a lattice decoration. For (pre-)baking the pies, AMF recommends a Den Boer Multibake tunnel oven with impingement heating or a direct-fired system.

For industrial production, pizza lines are made to welcome any variations required. Accurate processes are a must for these flexible lines.

Royal Smilde is known for its rich diversity of sweet and savory baked creations. Either sold under its own labels, through collaborations, or as private labels, the products made by the Dutch bakery are in growing demand worldwide. A very flexible production line helped them increase production volumes, built by AMF Bakery Systems (Tromp). Particular care was given to automating apple turnover production, namely – dough folding into a triangle.

ECD will bring its thermal profiling technology to iba in October. The handheld M.O.L.E.™ EV6 sets a new benchmark for thermal data loggers, delivering instantaneous data access and intuitive control – now with a full-color touchscreen display. In addition to the six-channel M.O.L.E. EV6, the company’s BreadOMETER™, CakeOMETER™, and OvenBALANCER™ sensors will be demonstrated at the stand.

At interpack, Syntegon is presenting a flexible line concept for packaging sensitive baked goods – from product distribution to case packaging. The seamlessly integrated packaging system comes with several novelties.

Packaging affects the state of the product throughout the supply chain. Identifying the best packaging process and materials ensures all types of baked goods make it from plant to table, exactly as intended.

As gluten-free bakery is decisively increasing its foothold into the mainstream market, growing by about 25% each year, research seeks to improve product taste, texture and nutritional profiles.