Unique eating experiences are a defining characteristic of snacking; they are especially expected when the choices are cakes and pastries. Corresponding production lines are designed to follow suit. AMF Bakery Systems customizes its equipment to match the need for product diversity, in any market segment, from fresh, to frozen or bake-off, to cover all (present and future) bases. Process efficiency is at the core.

For the production of cakes and pies, AMF Bakery Systems provides a modular system developed by AMF Tromp, which includes an AMF Den Boer tunnel oven. In this structure, automated lines can be customized for various needs and capacities, having in mind current and future throughput needs. A variety of products in these categories can be manufactured with dedicated lines developed by companies within the AMF Bakery Systems family, from fruit cakes to muffins and meat pies – to name a few widely different flavors and textures.

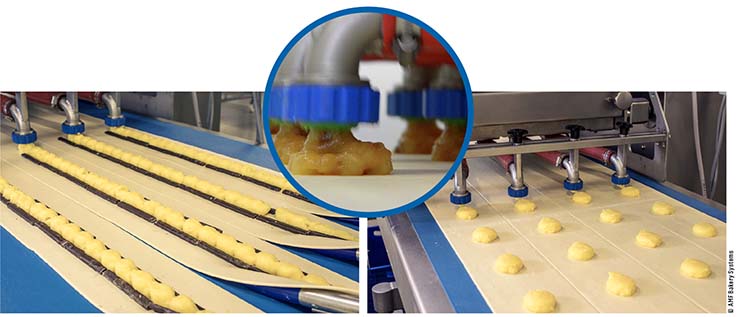

Automation features enable control of every step of the baking process, including depositing, air circulation and – essential for decision-making first impressions – decorating. With a variety of mixing, baking, cooling solutions and special units that can be combined with process optimization in mind, the cake line is very flexible, and can be designed according to precise production requirements. “Complete system solutions include everything from mixing to depositing and baking, to cooling and conveying. The decorating system itself can be customized for various methods such as topping, glazing, strewing, or injecting, to create any number of on-trend products: single-packed cakes, cupcakes, muffins and more,” Hans Besems, product manager at AMF Tromp, details. Both pastries and cakes greatly benefit from personalization with unique, creative shapes and finishing touches. For decorations, any or all of these methods with their corresponding equipment can be used to apply several kinds of materials. For instance, three decorations can be added onto (and into) the same product: a muffin or a donut cake can be injected, covered with (whipped) cream and topped off with sprinkles or nuts. Topping and decorating equipment can be used flexibly for smaller or longer runs; multiple decorating stations can be placed along the line for a streamlined process, or with changeovers on smaller lines.

The modular setup makes AMF cake and pastry lines flexible and allows them to support a wide range of products and sizes. The standard laminating and depositing sections can divert as needed to product-specific solutions that are flexible to change. The final layout of an AMF cake line will be determined by the specific production requests and the desired volumes, resulting in different lines of the same name. Some are mono-lines, dedicated to one product, while, in other projects, AMF engineers build the line for a variation of dozens of products per day. Production capacities can also be adjusted significantly: “Any volumes can be produced, starting from the capacity of one line, which can be multiplied by mirroring lines and using multiple lines with big tunnel ovens,” explains Besems.

Cake lines can be equipped with a Tromp piston injector, which works with various types of fillings. “We offer double jacket hoppers to heat fillings or cool them for optimal processing. Chocolate paste, for instance, needs to be warm to flow better in the injecting process.” Dosing speeds can be flexibly adjusted to different requirements, and different injecting solutions can be used. The injector’s head is interchangeable, meaning it can be replaced with a new, clean one and be ready to run again in a matter of seconds, he explains.

Lamination is another process that can be flexibly handled. The Tromp laminating and sheeting line is at the core of AMF’s pastry lines, producing stress-free laminated dough or using extrusion for high-speed lamination. The end product dictates all process requirements, including the choice of laminating technology and method. For Danish pastries and croissants, the low-stress laminating technology is the preferred option, for example, because it gives the products a more open, aerated texture and preserves the dough characteristics intact. Puff pastries such as sausage rolls, cheese rolls, palmiers, or vol-au-vents benefit more from the extrusion technique, which helps create more layers that are stable throughout handling. “Our Tromp technology offers gentle, low-stress dough handling and fewer falling heights, to retain product quality consistently over time,” says Besems.

“The decorating system itself can be customized for various methods such as topping, glazing, strewing, or injecting, to create any number of on-trend products.”

Hans Besems, product manager at AMF Tromp

Complete process control

AMF systems closely monitor production for steps where efficiency can be increased. Recipe following systems are integrated into all AMF complete lines, cake lines included, to save a very important resource: time. They determine when, and then automatically start a new production run at the start of the line as soon as it is possible, while the previous run is still in the oven. With products in various production stages on the line at the same time, the system will adjust part by part to synchronize multi-tasking and save time.

The company developed new tools to further optimize production by closely monitoring oven activity: “To keep efficiency and productivity up, short change-over times are required, and ovens need to be loaded and filled to capacity where possible. This is why we have introduced the new Sustainable Oven Service,” he explains. It uses oven data in real-time to provide the bakery team with recommendations on how to improve oven management. It helps increase production volumes and process efficiency, while the energy use (gas consumption) needed is lowered by up to 20%, the specialist says.

Proprietary software designed by bakers is integrated to complete the management of the lines. In addition to the Sustainable Oven Service, AMFConnect also helps to manage information and coordinate operations, by connecting different types of equipment, systems and the processes

associated with each. With smart machines, supported by (remote) data analysis and customer support, AMF lines can operate 24/7 if needed, without issues that would cause disruptions, the specialist emphasizes.

Profitable and mindful production

For all supported product categories, the design of the cake line takes into consideration sustainability, digitalization, minimizing waste and increasing automation with smart machines, the specialist lists.

“Ingredient use and savings are key topics in our sustainable design of future machines and lines,” he says. For example, replacing the waterfall method with targeted topping makes strewing accurate and can bring significant ingredient savings. However, waterfall topping is still the best solution for high production speeds; this is where recycling systems help to eliminate wasting valuable ingredients. Digital imaging and quality control systems also help to minimize waste and optimize quality output. Consequently, the OEE goes up and only products precisely matching the presets come out of the line. “Our smart applicator is the perfect solution here, as it takes images of each product on the line, and the machine (the topping applicator) learns and adjusts its working algorithm; it is mainly data-driven, which results in better output and quality,” illustrates Besems.

Savings can also be made in the energy required by the line. The AMF equipment is designed to use less energy and to require less air circulation. As it is equipped with servo-driven motors, this translates into lower energy consumption over time. Its hygienic design also helps save water for cleaning, a step forward towards sustainability.

Automation, as requested

The cake depositing process is fully automated, and so are baking and cooling. The line’s level of automation will be tailored to the bakery’s size and the desired production volumes. A semi-automatic line is also very common in many countries, where manual labor still is an important part of the process, AMF observes. A number of processes can be performed manually – and can be gradually automated later – including pan handling, decorating and packaging. Overall, automation is a growing request.

Conversely, AMF also delivers high-capacity cake lines that deposit, bake, cool, and decorate 100,000 cupcakes or muffins per hour, and which can then flow-pack them individually.

Looking ahead

Looking at the bigger (production) picture is a way of reaching the full potential of this line. Its custom design should consider space and time: “Always preserve space for future capacities, be it new products, new plans, or any number of additional projects,” Besems recommends. In this way, the capacity of such cake and pastry lines can be extended at a later time: “If our vision at the beginning of the project was right, we will have calculated for growth and expansion, and our make-up lines or proofers and ovens have room to grow. That is the big benefit of the modular design philosophy; doubling a certain part of the process is easy to accomplish,” he adds.

Equipment changeovers also take time from production. To minimize downtimes, cake and pastry lines are designed with easy access to crucial components, so that they can be changed fast, without tooling. “Units fit in specific positions, but are also flexible, such as C-frames, for example, to run exactly as designed by our engineering teams and product managers,” AMF Tromp’s product manager elaborates.

A line can also be revised and updated in time, at a significantly lower cost than the investment in a new line: existing hardware can be altered with new, modern components that bring the factory up to date, the oven capacity can be increased, and software updates will also radically improve older lines. “We are receiving considerable requests for such revisions that modernize the factory floor and machine park,” he shares. AMF’s Customer Care provides lifetime support for its machines – Den Boer systems and service are behind keeping a tunnel oven operational for over 50 years, for example.

Among trends, the company also observes increasing efforts to avoid waste and food spillage in retail and supermarkets. Correctly anticipating consumption and producing only what is ordered is key, in addition to single-serving portions, in this regard. Moreover, as the frozen food segment continues to rise, so does the range and volume of frozen bakery goods for bake-off. Besems concludes: “The sky is the limit for the product variety supported by these lines.”