MECATHERM launches M-DAN oven

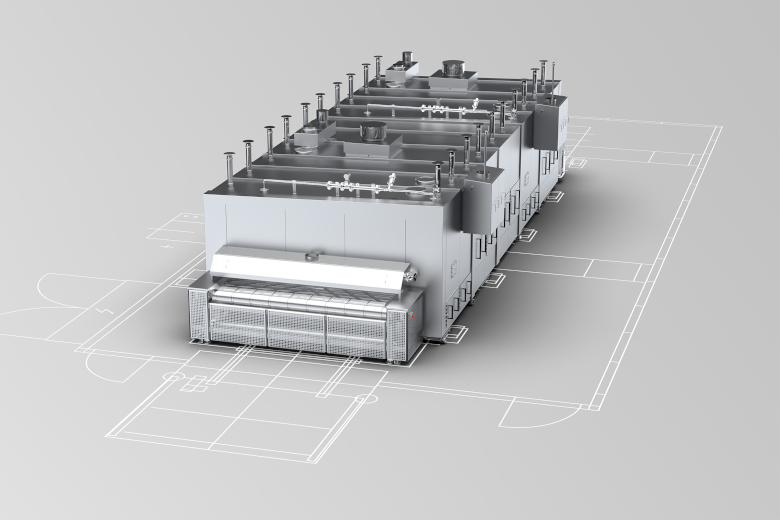

MECATHERM introduced its new M-DAN Oven, an evolution of the FDAN Oven technology, at interpack. The M-DAN Oven is dedicated to the production of delicate products and its design prioritizes hygiene and food safety.

MECATHERM introduced its new M-DAN Oven, an evolution of the FDAN Oven technology, at interpack. The M-DAN Oven is dedicated to the production of delicate products and its design prioritizes hygiene and food safety.

There are clear requirements for the proofing process. The dough may be resting, but its transformation process does nothing but rest. The question is, always, how to improve the process? Technology brings new answers.

MECATHERM will introduce its latest advances to tackle the sustainability and digitalization challenges in the manufacturing of baking and sweet goods. The French specialist will showcase its complete solutions at the show, focusing on solutions to optimize energy efficiency, a new, easy-to-clean oven dedicated to delicate products, and its latest digital solutions.

There are clear requirements for the proofing process. The dough may be resting, but its transformation process does nothing but rest. The question is, always, how to improve the process? Technology brings new answers.

This year, the French specialist focuses on solutions for energy efficiency, the new, easy-to-clean M-DAN oven and new digital solutions for industrial performance. MECATHERM is launching the new M-DAN Oven, with an improved hygienic design that includes wash-down capability.

Loïc Le Denmat, patisserie expert at MECATHERM, is preparing a series of knowledge-sharing videos, called ‘Ask Loïc’.

Raymond Nogael started a new role as the President and CEO North America – USA and Canada at MECATHERM, based in Toronto.

Among the solutions MECATHERM is presenting at IBIE, new digital services will debut, providing tools to help optimize process efficiency.

MECATHERM will highlight the M-Care, a new digital solution helping industrial bakers to optimize their performance. Live demonstrations will be organized to showcase its features.

Baking a vast range of high-quality products is only the start of what cutting-edge tunnel ovens can do.

With over 8,000 new patisserie product launches every year, the challenge for industrial bakers is to diversify their offers by developing innovative creations that also pass nutritional checkpoints and provide an exciting eating experience, through an efficient manufacturing process.

The trend for artisan quality brings forth a wealth of delightful, premium breads and baguettes, with texture and flavor characteristics nothing short of magic. It takes exact science and technology to perfect the process, however. Dedicated lines preserve the tradition of the technique with increased process efficiency.